Water is an essential resource, but its quality can significantly impact various industrial, laboratory, and household applications. Among the different types of purified water, demineralised water holds a unique position.

Understanding demineralised water, its production process, and its uses are crucial for making informed decisions about its application. This blog aims to explore the advantages and disadvantages of using demineralised water, providing a comprehensive understanding to help you determine if it is the right choice for your needs.

Table of Contents

ToggleWhat is Demineralised Water?

Demineralised water, also known as deionised water, is water that has had almost all of its mineral ions removed, such as calcium, chloride, sulfate, magnesium, and sodium. This high-purity water is produced through the demineralisation process, which involves removing dissolved salts and minerals.

How Demineralised Water is Produced?

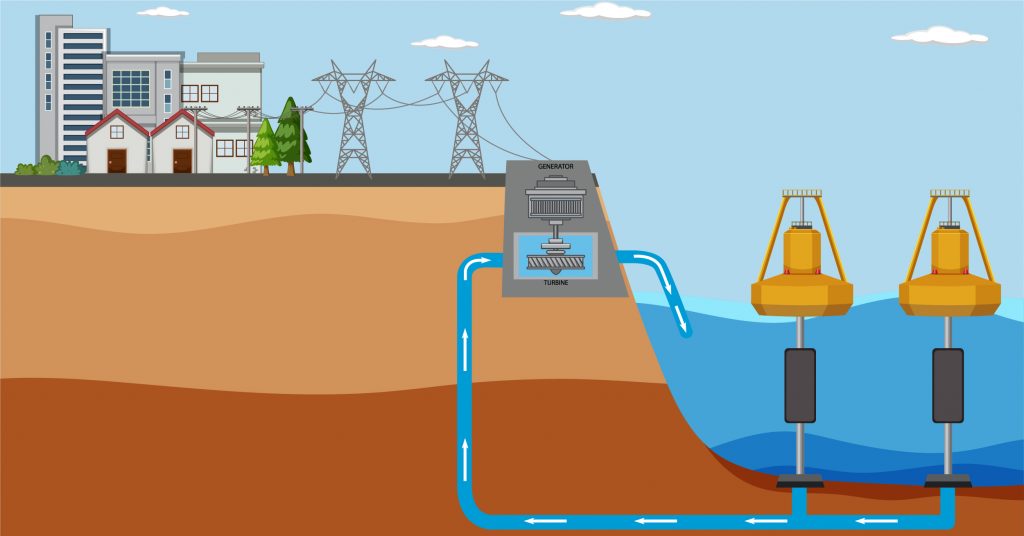

The demineralisation process typically involves two primary methods: ion exchange and reverse osmosis.

-

- Ion Exchange: Demineralised water uses ion-exchange resins to replace unwanted mineral ions in the water with hydrogen and hydroxide ions, which combine to form pure water molecules. The process involves passing water through cation- and anion-exchange resins that trap and exchange ions.

- Reverse Osmosis: In reverse osmosis, water is forced through a semipermeable membrane that allows water molecules to pass while blocking dissolved salts and impurities. This method is highly effective in removing a broad range of contaminants.

Advantages of Using Demineralised Water

- Purity: Low mineral content reduces scale buildup and interference in industrial processes.

- Improved Efficiency: Enhanced performance in cooling systems, boilers, and manufacturing.

- Extended Equipment Life: Reduced wear and tear on machinery and appliances.

- Quality Control: Consistent water quality for sensitive applications (e.g., pharmaceuticals, laboratories).

- Cost-Effectiveness: Lower operational costs in certain applications due to reduced maintenance.

- Versatility: Suitable for a wide range of industrial and scientific uses.

- Environmental Benefits: Lower environmental impact compared to other water purification methods.

- High Compatibility: It works well with most industrial equipment and processes.

Disadvantages of Using Demineralised Water

- Corrosiveness: Potential for increased corrosion in metal pipes and equipment.

- Limited Nutritional Value: Lack of essential minerals for human consumption.

- Environmental Impact: Energy and resources required for the demineralisation process.

- Taste Issues: Flat taste when used as drinking water.

- High Initial Cost: Investment in demineralisation systems and ongoing maintenance costs.

- Storage Issues: Requires proper storage to prevent contamination.

- Maintenance Requirements: Regular monitoring and maintenance of demineralisation equipment.

- Potential Health Risks: Long-term consumption may lead to mineral deficiencies.

Ion Exchange: Leading the Way in Demineralised Water Solutions

INDION New Generation Swift Softener (Short Cycle Softening Plant):

The INDION New Generation Swift Softener is designed to remove scale-forming ions like calcium and magnesium from water effectively. Its standout feature is the shorter regeneration time, making it ideal for short-cycle operations. This lightweight and easy-to-install system boasts a quick 30-minute regeneration cycle. Assembled and tested at the factory, all units are ready for installation and commissioning within a day. With auto-operation and low maintenance, it ensures hassle-free usage. Key features include an automatic unit with a multiport valve that can withstand pressures up to 5.5 kg/cm2, a special grade of monosphere resin, low wastewater volume, and a short operating cycle of just 3 hours. It tolerates hardness up to 600 ppm and is constructed with durable fiber-reinforced plastic (FRP). Available in seven models, it offers flow rates ranging from 3.5 m3/h to 20 m3/h, catering to various requirements.

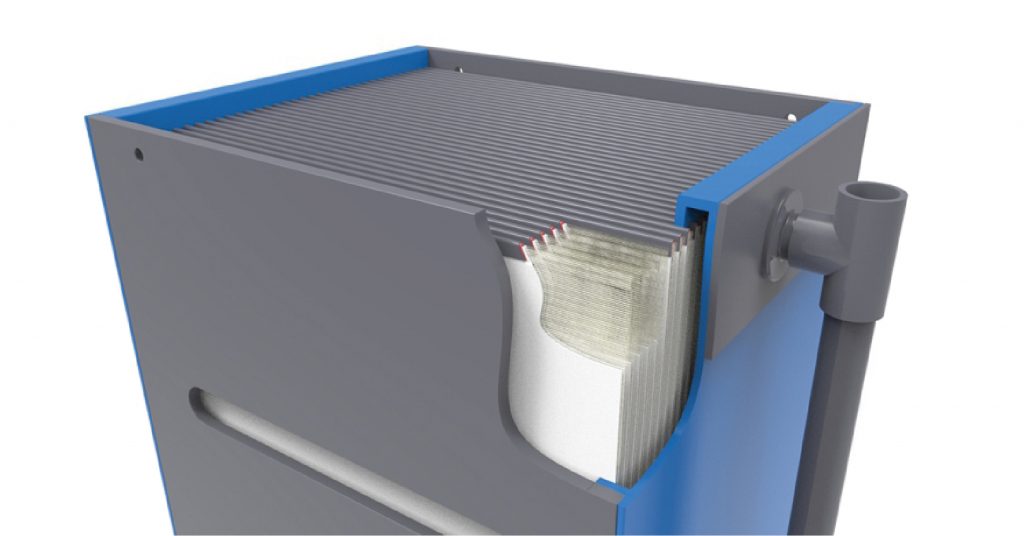

INDION Layered Bed Anion System

The INDION® Layered Bed Anion (LBA) unit is an innovative solution to maximize efficiency and minimize costs. This single-vessel system combines two types of resins, INDION LBA-WB and INDION LBA-SB, in a layered configuration with downflow service. This setup delivers the high chemical efficiency of a traditional two-bed system within one vessel, significantly reducing the need for additional equipment, piping, and valves. The result is excellent treated water quality and optimal use of regenerants, making the system both cost-effective and efficient. The INDION LBA system offers several advantages, including capital cost savings, a smaller footprint, high throughput capacity, and lower operating costs. Its contemporary design also ensures easy integration into existing systems, providing the lowest cost of production for demineralized water.

INDION Layered Bed Cation System

The INDION® Layered Bed Cation Unit is an innovative single-vessel system featuring layers of two resins. It combines INDION weak acid cation resin on top of INDION strong acid cation resin with a downflow service. This design delivers the high chemical efficiency of a two-bed weak acid cation and strong acid cation system within one vessel, eliminating the need for additional vessels, associated piping, and valves. The system enhances the chemical regeneration of the strong acid-cation resins, ensuring superior treated water quality and optimal regenerant utilization. Key advantages include capital cost savings, a lower footprint, and high efficiency in chemical usage due to its substantial throughput capacity.

INDION Elegant: Advanced Twin Bed Deioniser

The INDION Elegant system revolutionizes water treatment with its twin-bed deioniser incorporating state-of-the-art counter-current flow ion exchange technology previously only available in large, custom-designed plants. Utilizing strong acid cation (SAC) and strong base anion (SBA) resins in columns, the system offers optional features like a degasser tower (DGT) and a layered bed anion (LBA) column to produce high-quality demineralized water at significantly lower capital and operating costs. The exceptionally compact, skid-mounted design on a corrosion-resistant frame includes stainless steel pumps and offers a standard range of 10–120 – 120 m³/h in either manual or PLC automatic control modes. It uses INDION uniform particle-size resins in a counter-current mode to produce water with a conductivity of 1–10 μS/cm and reactive silica of 10–30 ppb. Optional HMI provides system status read-outs, audible alarms, and no flow alarms. With a smaller footprint than conventional demineralizer plants, INDION Elegant ensures minimal installation and commissioning time and cost.

INDION SWIFT 5Gx Series: Short Cycle Rapid Regeneration

The latest INDION Swift 5Gx series brings a family of automatic twin-bed deionisers, utilizing advanced counter-flow ion exchange technology, previously exclusive to large custom plants. With a regeneration time of just 35 minutes and a minimum service cycle of four hours, the need for standby plants and large water storage volumes is significantly reduced. This exceptionally compact series is skid-mounted on a corrosion-resistant frame, which includes a stainless steel multi-purpose pump. This pump not only optimizes plant performance during service and regeneration but also offers several recirculation options to maintain high water quality in the treated water tank. Key features of the INDION Swift 5Gx series include enhanced bacterial control, reduced treated water storage costs, near-neutral effluent, and high-quality treated water with conductivity between 1-10 µS/cm. Additionally, it boasts low operating costs, a quick start-up time, and a low footprint, making it an efficient and economical solution for high-quality water needs.

INDION SWIFT Plus Demineralizer

The latest Indion Swift Plus range features advanced automatic twin bed deionizers with state-of-the-art counter-flow ion exchange technology, previously found only in large, custom-designed plants. These rapid regeneration units are volume-controlled and pre-programmed in a PLC based on the type of feed water, allowing for a swift 35-minute regeneration after a minimum service cycle of two hours. This minimizes the need for a standby plant and reduces the storage of large water volumes. The Indion Swift Plus is exceptionally compact, skid-mounted on a corrosion-resistant frame, and includes a stainless steel multi-purpose pump. Key features include mixed-bed quality water at minimal cost, an additional cation polishing stage for enhanced quality, an average resistivity of purified water at 10 MΩ·cm with neutral pH, a small footprint, and high chemical efficiency. The Swift Plus delivers up to 330 m³/day on feed water of 100 ppm total anion feed, with no need for additional regenerant chemicals and a quick 35-minute regeneration time.

INDION New Generation: Two-Bed Deionisers with Degasser Tower

The INDION Industrial Two-Bed Upflow Deionisers Type CA and CDA units are designed to meet the requirements for producing small quantities of demineralised water, with flow rates ranging from 1.0 to 15.0 m3/h. For larger demands, flow rates can be increased to 35 m3/h by installing multiple units in parallel. These free-standing, compact units are easy to install and maintain. The CA units come equipped with all necessary components for the regeneration of ion-exchange resins. Constructed entirely of plastic, they are corrosion-resistant and require minimal maintenance. The modular design allows for easy capacity enhancement, making them a flexible and efficient solution for your deionisation needs.

Conclusion

Demineralised water offers numerous advantages, such as high purity, improved efficiency, and extended equipment life, making it ideal for various industrial and laboratory applications. However, it also has disadvantages, including potential corrosiveness, high initial costs, and limited nutritional value for human consumption. Balancing these pros and cons is essential to determining if demineralised water is the right choice for your specific needs.

Contact Ion Exchange today to learn more about the use of demineralised water in your applications.