Water treatment plays a crucial role in addressing water quality challenges in India. With rising population and industrialization, the demand for clean, safe water has never been higher. Among the advanced technologies available, the ultrafiltration process has emerged as a key solution for achieving superior water quality. This blog provides an in-depth guide to the ultrafiltration process, its applications, and its benefits in water treatment systems in India.

Table of Contents

ToggleWhat is the Ultrafiltration Process?

The ultrafiltration process is a membrane-based water treatment technology that removes suspended solids, bacteria, viruses, and other contaminants from water. It uses an ultrafiltration membrane process, which operates as a physical barrier, allowing only water and certain dissolved substances to pass through while retaining impurities.

Ultrafiltration is highly effective in producing clean water for various applications, including drinking water, industrial processes, and wastewater treatment. Its ability to deliver reliable performance with minimal chemical usage makes it a preferred choice in India’s water treatment sector.

How Does the Ultrafiltration Process Work?

The process of ultrafiltration involves the use of membranes with microscopic pores ranging from 0.01 to 0.1 microns. These membranes act as a filter that separates contaminants from water. The process includes the following steps:

- Pre-Treatment

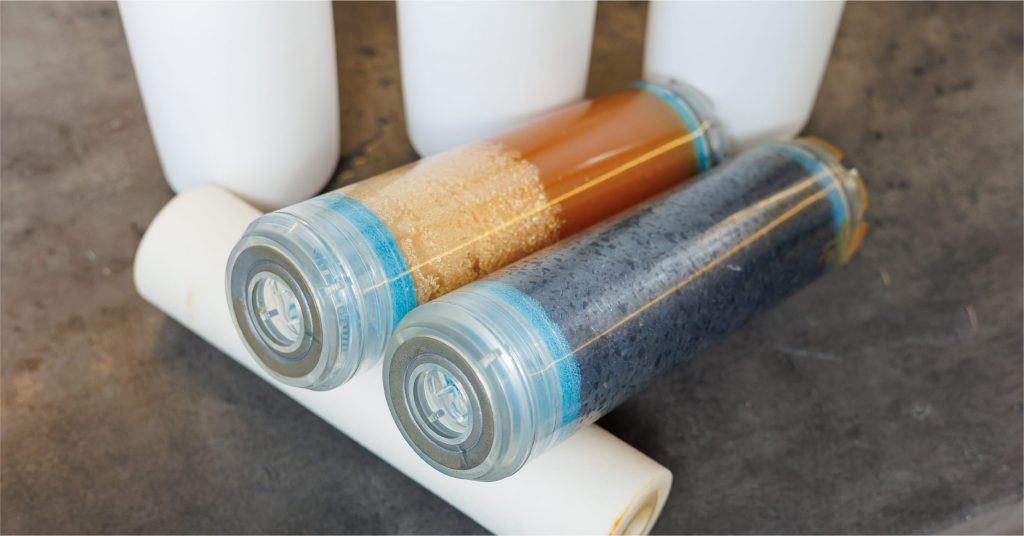

Water is passed through a pre-treatment system to remove larger particles and debris that could damage the ultrafiltration membrane.

- Membrane Filtration

The ultrafiltration membrane process begins as water is forced through the membranes under pressure. Suspended solids, microorganisms, and high-molecular-weight substances are retained, while water and smaller molecules pass through.

- Backwashing and Cleaning

To maintain efficiency, the system periodically undergoes backwashing or cleaning to remove accumulated impurities on the membrane surface.

- Post-Treatment

In some cases, the filtered water undergoes additional treatment, such as disinfection or reverse osmosis, for specific applications.

Applications of the Ultrafiltration Process in India

The ultrafiltration process is widely used in various sectors in India due to its versatility and effectiveness. Some of its key applications include:

- Drinking Water Treatment

Ultrafiltration ensures the removal of harmful microorganisms and suspended particles, making it suitable for producing safe drinking water.

- Industrial Water Treatment

Industries use the ultrafiltration membrane process to treat water for manufacturing, cooling, and boiler feed applications. It helps improve operational efficiency and reduce equipment wear.

- Wastewater Treatment

The ultrafiltration process in wastewater treatment is effective in reclaiming water for reuse, reducing environmental pollution, and conserving freshwater resources.

- Pre-treatment for Reverse Osmosis

Ultrafiltration acts as a pre-treatment step in reverse osmosis systems, protecting the membranes and enhancing their performance.

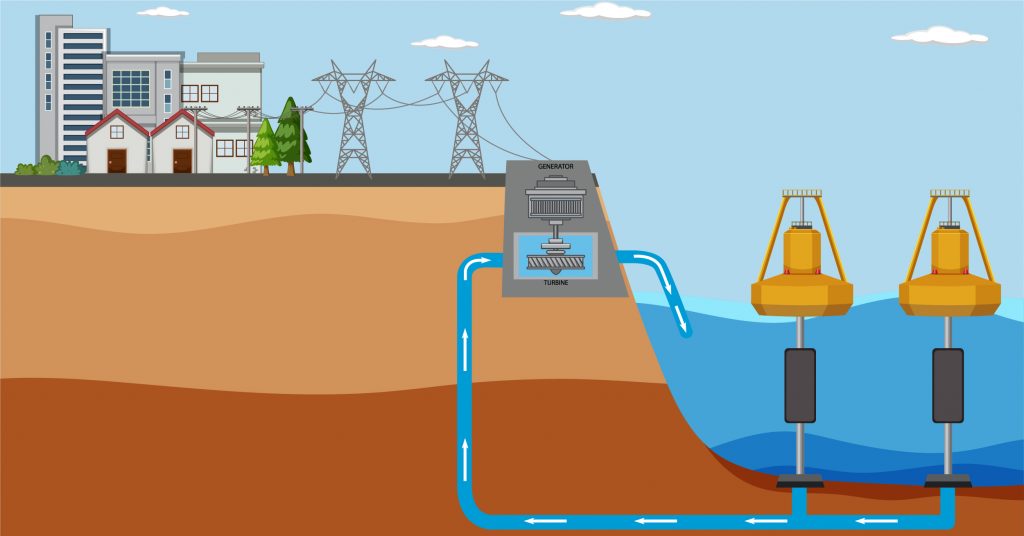

- Desalination Plants

In coastal regions of India, ultrafiltration is used in desalination plants to remove impurities before the water undergoes further desalination processes.

Benefits of the Ultrafiltration Process

1. Superior Filtration Performance

The ultrafiltration membrane process effectively removes bacteria, viruses, and suspended solids, providing high-quality treated water.

2. Reduced Chemical Usage

Unlike conventional treatment methods, ultrafiltration requires minimal or no chemical additives, making it an eco-friendly option.

3. Compact Design

Ultrafiltration systems are compact and modular, requiring less space compared to traditional treatment systems.

4. High Water Recovery Rate

The process of ultrafiltration achieves a high recovery rate, ensuring efficient use of water resources.

5. Low Maintenance

Ultrafiltration systems are designed for easy operation and maintenance, with automated cleaning cycles to enhance membrane longevity.

6. Energy Efficiency

The low-pressure operation of ultrafiltration systems reduces energy consumption, making them cost-effective.

7. Versatility

Ultrafiltration systems can treat water from various sources, including rivers, lakes, and industrial wastewater, making them suitable for diverse applications.

Meeting India’s Water Treatment Needs with Ion Exchange

Ion Exchange is a leading provider of water treatment solutions in India, offering a range of ultrafiltration systems designed to meet the diverse needs of its clients. The company’s expertise in water treatment ensures that each ultrafiltration system is tailored to the specific requirements of the application, whether it’s for residential, commercial, or industrial use.

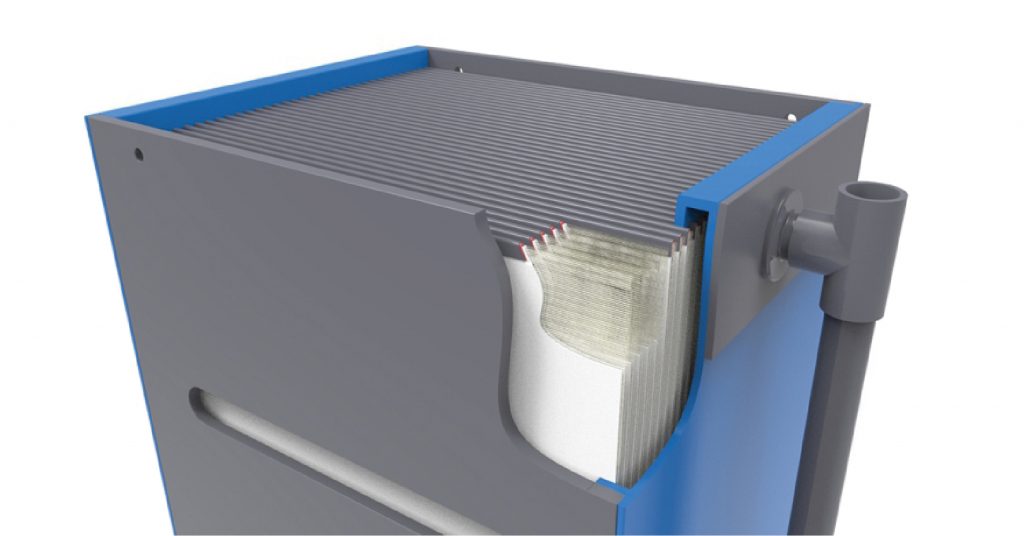

HYDRAMEM – Ultrafiltration Membrane

It is a tangential flow, a pressure-driven process that effectively filters particles based on their molecular size. With pore diameters ranging from 10 to 200 Å (0.001 to 0.02 microns), ultrafiltration membranes allow solvents and smaller species to pass through, resulting in a purified ultrafiltrate known as permeate, while larger particles are retained and concentrated. These membranes are reusable and can be cleaned with standard chemicals, making them highly efficient for continuous use. Ultrafiltration in process water treatment ensures the removal of nearly all particulate matter, suspended solids, bacteria, viruses, pyrogens, and colloidal materials, including non-reactive silica, iron, aluminum, and high molecular weight organics, making it essential for pharmaceutical and industrial applications.

Conclusion

Ultrafiltration is a highly effective water treatment technology that has found widespread application in India due to its numerous benefits. From providing high removal efficiency of contaminants to offering energy efficiency and low operational costs, ultrafiltration addresses the country’s water quality challenges. As India continues to grapple with water scarcity and the need for sustainable solutions, ultrafiltration offers a promising pathway toward ensuring safe, clean, and reliable water supplies. Whether for urban, rural, agricultural, or industrial use, ultrafiltration membranes play a crucial role in supporting Indonesia’s water treatment needs.

Connect with Ion Exchange experts today to learn more about ultrafiltration and how it can be applied in your specific situation.