The rapid pace of urbanization and growing population in India has led to unprecedented pressure on its water resources. Municipalities, industries, and communities face dual challenges of water scarcity and pollution. Untreated sewage is one of the largest sources of water contamination in the country, impacting public health, ecosystems, and the economy. Meanwhile, demand for clean water continues to grow. The urgent question is: how do we close this gap? The answer is sustainably treating wastewater and reusing sewage at scale.

Table of Contents

ToggleWhat is a Sewage Treatment Plant and Why Does It Matter?

A sewage treatment plant is a system intended to remove contaminants, suspended solids, and pathogenic microorganisms from sewage before safely discharging or reusing it. In India, where over 60% of sewage generated is not treated, sewage treatment plants are crucial to minimizing pollution in rivers, reducing waterborne disease, and recycling water for non-potable uses.

But treatment by itself is insufficient. The true transformation occurs through reconnecting sewage treatment with reuse—creating a valuable resource from wastewater for agriculture, industry, and even municipal use. This is where sustainable options for wastewater treatment become essential.

Challenges in India’s Sewage Management

Huge Quantities of Untreated Wastewater – Urban areas produce millions of liters of sewage on a daily basis, with considerable portions entering rivers and lakes without treatment.

- Infrastructure Deficiencies – Many cities lack waste treatment networks or plants that can accommodate an expanding wastewater load.

- Operational Limitations – Most wastewater plants have higher levels of downtime, costs of operation, and inadequate maintenance than are acceptable.

- Water Concerns – It is now an absolute necessity, not merely a little option, to recycle treated wastewater, given the depletion of groundwater resources and erratic precipitation.

These issues emphasize the need for wastewater treatment systems that are resilient, sustainable, efficient, and cost-effective.

Ion Exchange’s Role in Driving Sustainable Wastewater Reuse

Ion Exchange, a pioneer in water and environmental solutions, has been at the forefront of addressing the operational challenges faced by wastewater treatment plants. With a deep understanding of the industry’s pain points and a commitment to innovation, Ion Exchange offers state-of-the-art wastewater treatment plants and customized solutions to meet the unique needs of each facility.

Our wastewater treatment plant solutions offer wide applications and pioneer innovations in water management by recycling wastewater and reducing its source. Our integrated systems focus on waste management through product recovery and waste minimization, employing energy-efficient and cost-effective membrane technologies, advanced oxidation, and evaporation processes. These technologies conserve water by recycling wastewater and recovering valuable products for reuse, achieving zero liquid discharge objectives.

This not only provides our customers with a strong return on investment but also protects the environment. After conducting bench-scale and pilot plant studies and detailed site surveys, we select the most appropriate technologies and treatment schemes. Our designs cater to various industries, including power plants, fertilizers, electronics, electroplating, textiles, chemicals, food and beverage, pulp and paper, pharmaceuticals, and automobiles, ensuring optimal recovery and reuse of water and products.

Explore Ion Exchange’s Products

Ion Exchange’s comprehensive product line for wastewater treatment includes the following:

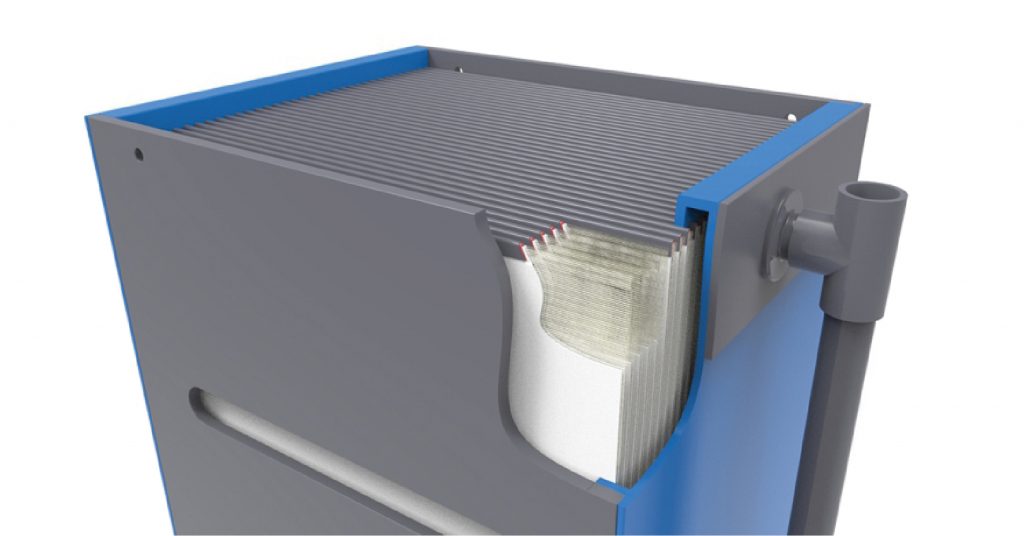

Ion Exchange’s wastewater treatment systems are designed to produce environmentally safe treated effluent and solid waste (sludge) suitable for disposal or reuse as fertilizer. Our pioneering solutions encompass water management through wastewater recycling, source reduction, product recovery, and waste minimization. The treatment process, comprising primary, secondary, and tertiary stages, is tailored to the wastewater characteristics and desired effluent quality. Our product range includes INDION® TADOX® (Advanced Photocatalytic Oxidation Process), High Rate Solid Contact Clarifiers, Anaerobic and Aerobic Systems, Membrane Bio Reactors, Packaged Sewage Treatment Plants, Packaged Waste Treatment Systems, Disinfection Systems, Odor Control Systems, Oil Screening and Grease Removal Systems.

Ion Exchange offers a comprehensive range of advanced wastewater treatment technologies, including continuous media filters, advanced oxidation systems, and membrane systems. The continuous media filters provide efficient solids removal, while the advanced oxidation systems employ powerful oxidants like ozone and hydrogen peroxide for the degradation of persistent organic pollutants. Additionally, membrane systems, such as ultrafiltration and reverse osmosis, enable superior separation and purification of treated effluents, ensuring high-quality water for safe discharge or reuse applications.

With over 60 years of proven expertise, Ion Exchange incorporates advanced effluent treatment processes, innovative membrane technologies, and state-of-the-art evaporation processes to maximize water recovery and achieve zero liquid discharge. Our solutions offer assured availability of water for process needs and low-end uses, savings through the recovery of valuable products for reuse, reduced water costs and freshwater requirements, and assured compliance with pollution control board regulations.

Why Choose Ion Exchange for Sustainable Wastewater Treatment?

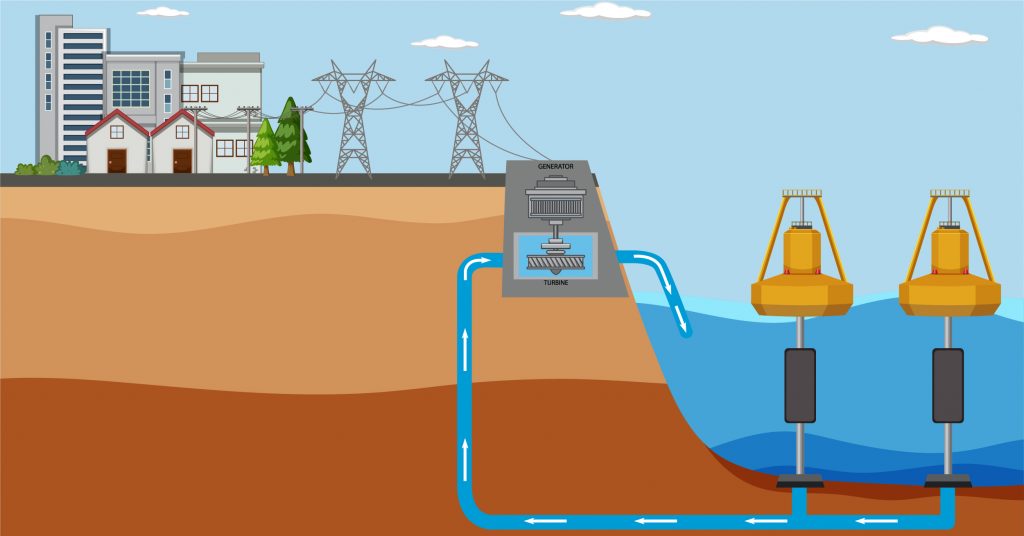

Sustainable Wastewater Reuse at Anjar, Gujarat

Ion Exchange, in partnership with the Welspun Group, has set up advanced sewage treatment and recycling plants with a combined capacity of 70 MLD in Anjar, Adipur, and Gandhidham. This public-private partnership reduces the burden on municipal authorities, prevents pollution of the Nakti Creek in the Gulf of Kutch, and provides a reliable alternate water source for Welspun’s textile operations. Aligned with SDG 11 and SDG 17, the project has been recognized with the Government of India’s National Water Award in the Industrial category.

Sustainable Water Solutions for Textile Manufacturing in Ludhiana

Ion Exchange is partnering with a leading yarn manufacturer in Punjab to deliver comprehensive water and environment solutions for their greenfield project. With advanced systems including a 3400 m³/d WTP, 650 m³/d CTBD, 400 m³/d Softener, 135 m³/d EDI, 700 m³/d ETP, 150 m³/d STP, and a 26 m³/d ZLD with MVR, the project ensures reduced operational costs, maximum water reuse, and minimal wastewater discharge. These integrated solutions conserve water, cut freshwater dependency, and drive sustainable textile manufacturing.

Conclusion

India’s Water Future rests on the country’s ability to adequately address sewage management. Cultivating sustainable wastewater treatment for water reuse through modern sewage recycling is more than an environmental necessity; it is a priority for development and sustainability. Here at Ion Exchange, we are dedicated to creating that future by delivering transformative sewage treatment technology and sustainable water treatment methods, converting wastewater into a valuable resource.