Cooling towers are indispensable in industrial operations, from power plants and refineries to chemical, steel, and pharmaceutical industries. They regulate heat and maintain efficiency in large-scale processes, but their performance often depends on the quality of circulating water. Over time, suspended solids, dust, algae, and other contaminants accumulate in the system, reducing heat transfer efficiency and increasing operational costs. This is where the side-stream filter emerges as a game-changer. By continuously cleaning a portion of circulating water, the side stream filter ensures better purity, extended equipment life, and higher system efficiency.

Table of Contents

ToggleThe Growing Need for Cooling Tower Water Purity

In India, industries operate under challenging environmental conditions, with dust, pollutants, and varying water qualities putting immense strain on cooling systems. Traditional blowdown methods, while useful, are insufficient to address the steady build-up of suspended particles. Without proper treatment, issues such as scaling, fouling, corrosion, and biological growth arise, ultimately leading to system failures and costly downtime.

To address these challenges, industries are increasingly adopting the side-stream filter for cooling tower systems. This solution ensures continuous removal of suspended impurities and enhances overall cooling tower performance.

What is a Side Stream Filter?

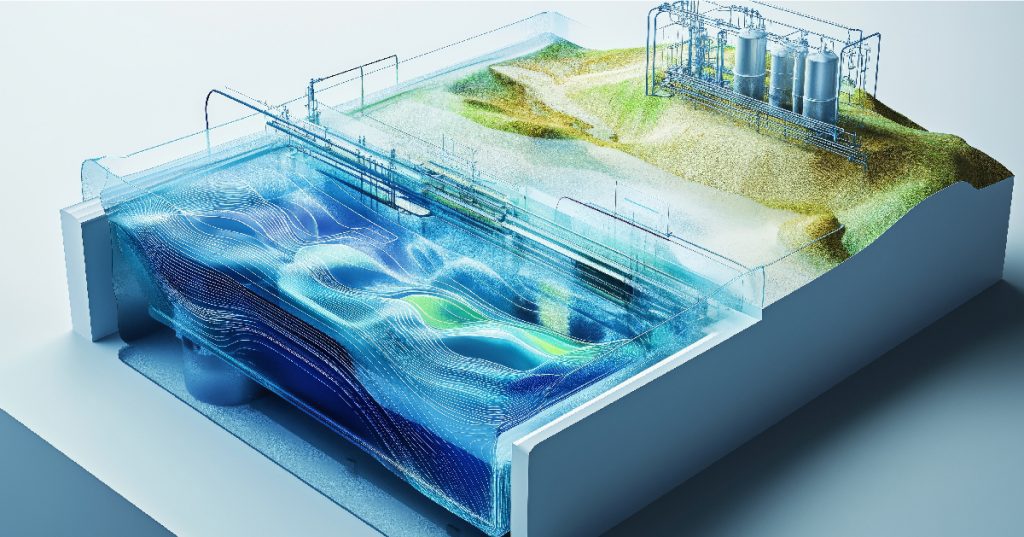

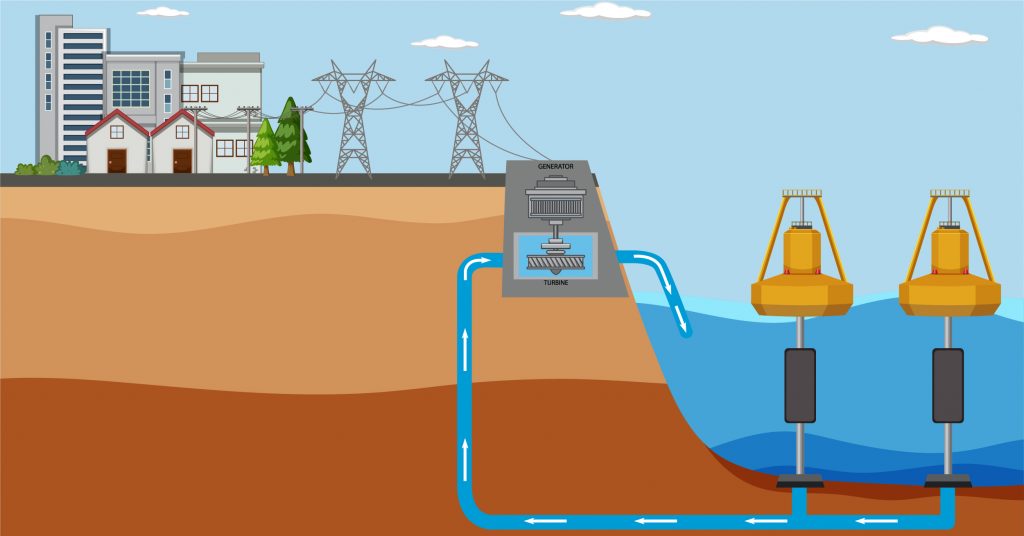

A side stream filter in cooling tower systems is designed to treat a portion—typically 5% to 10%—of the circulating water at any given time. Instead of attempting to filter the entire water volume in one cycle, it focuses on steady and consistent purification. Over multiple cycles, this approach ensures that the overall water quality in the cooling tower basin remains clean and free from excessive contaminants.

This filtering method is highly efficient, cost-effective, and requires minimal intervention, making it ideal for industries in India that face water scarcity and strict sustainability norms.

Benefits of a Cooling Tower Side Stream Filter

The adoption of a cooling tower side-stream filter brings multiple benefits for industrial operations:

1. Enhanced System Efficiency

By reducing suspended solids and impurities, side-stream filters prevent scaling and fouling on heat exchanger surfaces. This ensures maximum heat transfer efficiency and lowers energy consumption.

2. Improved Water Conservation

Since the side-stream filter helps maintain clean water in circulation, the need for frequent blowdown is reduced. This saves large volumes of water—a crucial advantage in water-stressed regions of India.

3. Extended Equipment Life

Clean water reduces corrosion, scaling, and microbiological growth, which directly extends the lifespan of cooling towers, pumps, and pipelines.

4. Reduced Chemical Dependency

With lower contaminant levels, industries can reduce the use of water treatment chemicals for controlling scale and bio-growth, thereby lowering costs and minimizing environmental impact.

5. Operational Reliability

Regular cleaning ensures uninterrupted operations, minimizes unplanned shutdowns, and supports consistent production output.

Types of Side Stream Filters Used in Cooling Towers

Industries in India use different types of side-stream filters depending on their operational requirements and water quality challenges:

- Sand Filters: Widely used for removing suspended solids and turbidity.

- Multi-Grade Filters (MGF): Designed to remove fine particles using multiple layers of media.

- Automatic Self-Cleaning Filters: Ideal for continuous operation without manual intervention.

- Cartridge Filters: Used for finer filtration requirements in specific industries.

The selection of the right side-stream filter for a cooling tower depends on factors such as particle size, water quality, flow rate, and industry-specific needs.

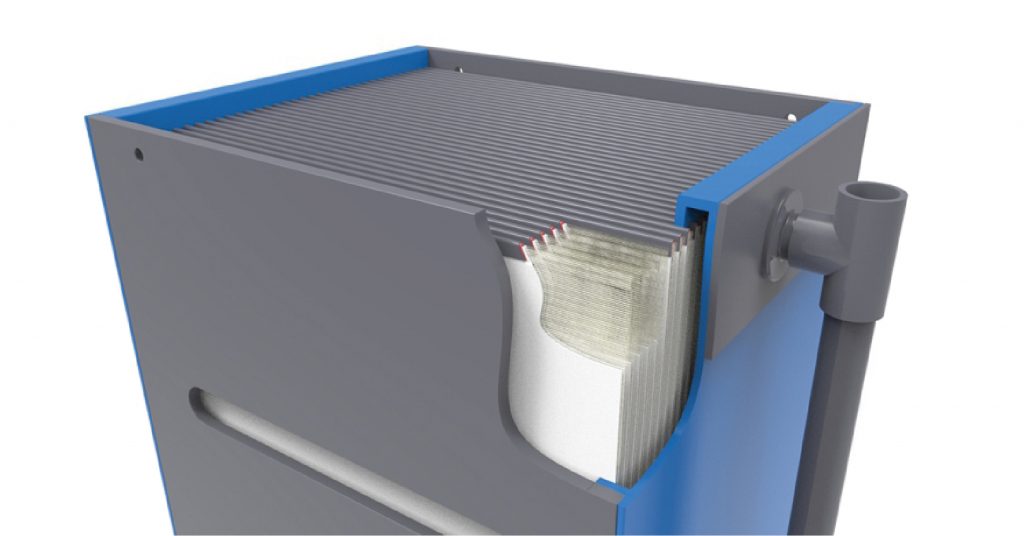

Ion Exchange Pressure Sand Filter for Reliable Suspended Matter Removal

The Ion Exchange Pressure Sand Filter is a robust filtration unit designed to remove suspended solids from water through a multi-layered media bed. Housed in a vertical or horizontal pressure vessel, the system includes frontal piping with valves, a graded sand bed supported by layers of silex and pebbles, a top distributor for even water distribution, and an efficient under-drain system to collect filtered water. Constructed using ASME Sec VIII, Div-I or IEI good engineering practices, it is available in MOC options such as MS, MSRL, and MSEP. During operation, raw water passes downward through the sand bed, capturing impurities treated with coagulants like alum. As filtration progresses, head loss increases, reducing flow until backwashing is required. The unit employs air scouring before backwash, which agitates the sand to effectively dislodge trapped particles, restoring filtration efficiency and allowing seamless return to service.

Conclusion

Maintaining cooling tower purity is no longer just about operational efficiency—it’s about sustainability, compliance, and long-term cost savings. A side-stream filter provides a simple yet revolutionary way to achieve this balance. By continuously purifying circulating water, industries can prevent scaling, conserve water, and extend equipment life.

As India’s industrial sector grows, the adoption of side-stream filters for cooling tower systems will play a pivotal role in ensuring sustainable operations.