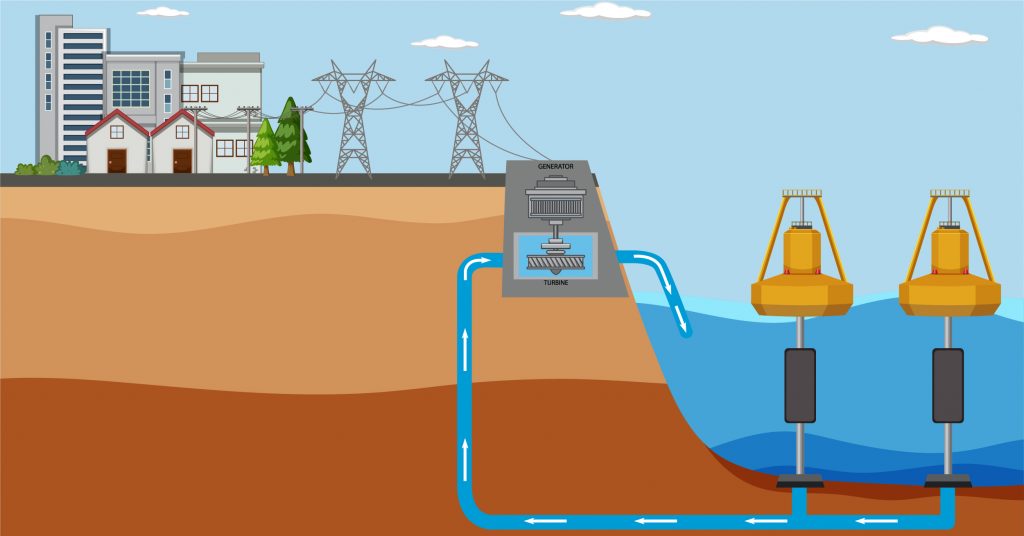

India’s urban and industrial sectors are experiencing rapid growth, and with this expansion comes a rising need for reliable and high-quality wastewater treatment. Municipal bodies, industries, and commercial complexes are increasingly turning to advanced technologies to meet pollution control norms, reduce environmental impact, and ensure treated water can be safely reused. Among these advanced solutions, the membrane bioreactor (MBR) has emerged as one of the most efficient and dependable technologies for achieving extremely low Biological Oxygen Demand (BOD) levels — often as low as 5 mg/L, translating to nearly 99% BOD removal.

Modern membrane bioreactor MBR technology combines biological degradation with membrane filtration, making it ideal for India’s increasingly strict discharge standards and water reuse needs.

Table of Contents

ToggleWhy BOD Removal Is Critical?

BOD (Biological Oxygen Demand) indicates the amount of oxygen microorganisms require to break down organic matter in water. High BOD levels mean high pollution levels.

India’s regulatory bodies, including the CPCB and SPCBs, mandate stringent BOD limits for treated wastewater discharged into surface water, used in irrigation, or reclaimed for industrial reuse.

Traditional technologies like activated sludge systems often struggle with fluctuating loads, limited space, and inconsistent effluent quality. This is where MBR systems provide a breakthrough.

What Is a Membrane Bioreactor?

A membrane bioreactor integrates two processes:

- Biological treatment – using microorganisms to break down organic pollutants.

- Membrane filtration – using ultrafiltration (UF) or microfiltration (MF) membranes to physically separate clean water from suspended solids, biomass, and pathogens.

This combination results in superior effluent clarity, extremely low BOD and COD levels, and high-quality treated water suitable for reuse.

How MBR Achieves 99% BOD Removal?

1. High Biomass Concentration

MBRs allow higher MLSS (Mixed Liquor Suspended Solids) concentrations than conventional systems. This increases microbial population and improves degradation efficiency.

2. Complete Solid-Liquid Separation

The membrane acts as a physical barrier, ensuring no suspended solids escape — even at high organic loading rates.

3. Enhanced Biological Activity

Stable environments, high oxygen transfer, and controlled parameters ensure faster and more efficient organic breakdown.

4. No Dependency on Clarifiers

Since membranes replace secondary clarifiers, MBRs eliminate inefficiencies in settling, a common cause of poor BOD performance in traditional systems.

5. Consistent Output Quality

Even with fluctuations in influent quality, MBR systems consistently produce high-quality effluent with BOD < 5 mg/L.

This is why MBRs are preferred in industries and municipalities that require predictable, high-purity wastewater output.

Membrane Bioreactor Types Used in India

Different membrane bioreactor types are utilized depending on treatment goals, space availability, and energy requirements:

1. Submerged (Immersed) MBR

- Membranes are placed inside the bioreactor tank

- Lower energy consumption

- Widely used for municipal wastewater and STPs

2. Side-Stream MBR

- Membranes are installed outside the bioreactor.

- High flux and performance

- Preferred for industrial effluent with higher strength

3. Hybrid / Integrated MBRs

- Combine biological and advanced membrane processes.

- Suitable for complex industrial waste streams

These configurations allow flexibility in design while ensuring high efficiency.

Applications of MBR Technology in India

MBR systems are now widely adopted in:

- Municipal sewage treatment plants (STPs)

- Industrial wastewater treatment (textile, food & beverage, pharma, chemical, automobile)

- Commercial complexes and townships

- Hotels, resorts, hospitals

- Water reuse and recycling projects

- Zero Liquid Discharge (ZLD) schemes

The system’s ability to deliver consistent, high-purity water makes it ideal for India’s water-stressed regions.

Ion Exchange’s Expertise in Membrane Bioreactor Technology

Ion Exchange is among the trusted membrane bioreactor manufacturers providing advanced, energy-efficient, and space-saving MBR systems across India.

Green Manufacturing in Practice

MBR for our Ion Exchange Resin Plant at Ankleshwar

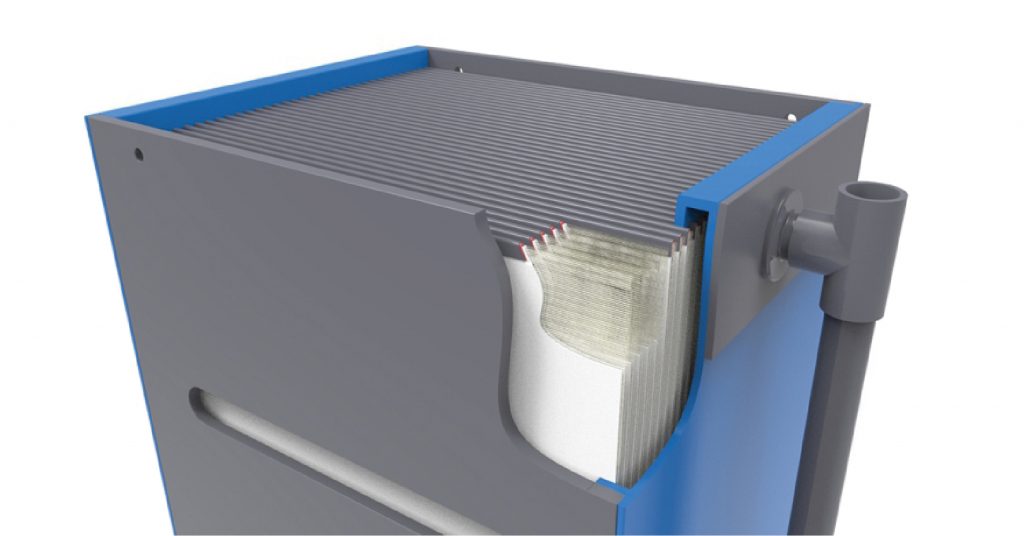

Ion Exchange’s plant, one of the largest ion exchange resin-producing units in India, is located in Ankleshwar, a well-developed industrial area in Gujarat. The fully automated facility produces various grades of resin, anion and cation gel, macroporous and isoporous, for water treatment as well as non-water and speciality applications. Ours was the first ion exchange resin manufacturing facility in India to receive ISO 9001:2000 and 14001 certification for quality and environmental compliance. It also has an FDA-approved facility for producing resins for applications in the pharmaceutical industry. Membrane bio-reactor section

Because of the cluster of industries, primarily chemical, in Ankleshwar and the inadequate treatment of complex chemical waste generated by them, the water table and the natural water resources around this industrial area have been heavily polluted. While our own plant had a fully operational effluent treatment system treating the waste streams to acceptable levels for discharge, our commitment to recover water from the effluent and reduce the load on the environment led us to initiate a first-of-its-kind project to extend the treatment of effluents by a series of state-of-the-art and sophisticated membrane systems.

The waste streams from the cation and anion plants, and the utility waste like boiler blowdown and demineraliser (DM) regeneration effluent, are segregated based on their constituent impurities and treated separately. The acidic water, wash water, boiler blowdown, and DM plant waste from both the plants are treated through a process which incorporates the high rate solids contact clarifier (HRSCC), hollow fibre ultra filtration, and reverse osmosis. The water recovered from these streams is taken back for process uses. Ultrafiltration section.

The stream comprising complex organics and the other biodegradable waste from the toilets is combined and treated by a process involving chemical treatment, HRSCC, advanced oxidation, and the MBR to recover water for reuse.

Conclusion

With increasing pressure on cities and industries to meet stringent environmental norms, membrane bioreactor MBR technology has become one of India’s most reliable solutions for achieving up to 99% BOD removal. Its ability to treat complex wastewater, operate in compact spaces, and deliver reuse-quality water makes it a cornerstone technology for the country’s sustainable future.