Water is a fundamental necessity in every aspect of life—domestic use, industrial processes, or agricultural needs. However, in many parts of India, raw water sources often contain dissolved impurities such as calcium, magnesium, iron, and other minerals. These contaminants contribute to water hardness and can adversely affect equipment, pipelines, and human health. This is where the ion exchange process plays a vital role in ensuring clean, safe, and soft water for various applications.

Table of Contents

ToggleWhat is the Ion Exchange Process?

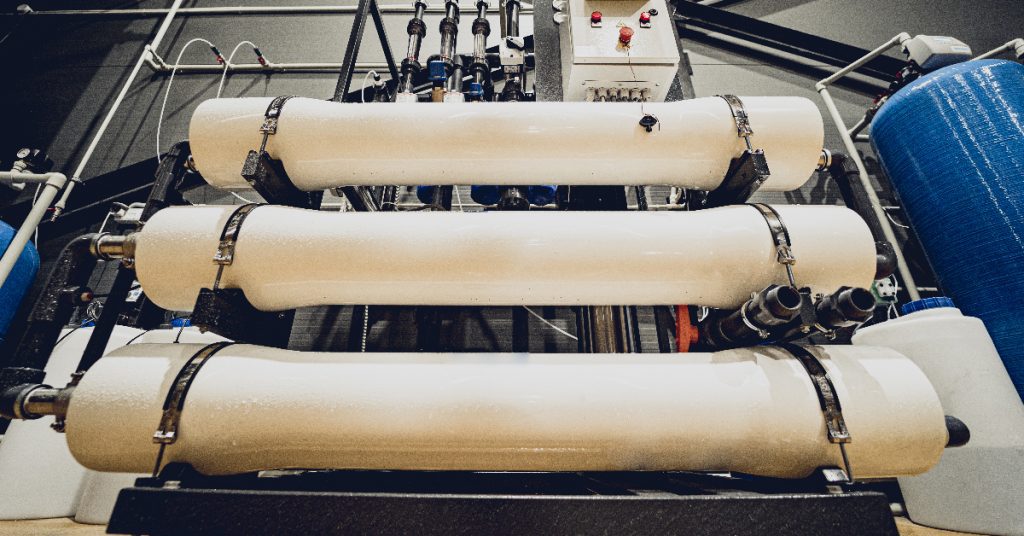

The ion exchange process is a chemical method used to remove undesirable ions from water and replace them with more acceptable ones. It works by exchanging ions in a solution with ions fixed to a resin. The resin, usually made of an organic polymer, is charged with sodium (for softening) or hydrogen and hydroxide ions (for deionization). As hard water passes through the resin bed, calcium and magnesium ions are replaced with sodium ions, effectively softening the water.

The ion exchange process in water treatment is widely used because of its efficiency, scalability, and cost-effectiveness. It not only improves water quality but also enhances the lifespan of water-handling equipment by preventing scaling and corrosion.

Importance of the Ion Exchange Process in India

India faces unique water challenges due to its diverse geography and population density. Groundwater, which is a primary source of water in many regions, often contains high levels of hardness and dissolved salts. In industrial belts and urban areas alike, the need for reliable water treatment solutions is growing rapidly.

The ion exchange process in water treatment has become an integral part of India’s efforts to provide safe and usable water. Whether it’s for residential use, commercial establishments, or manufacturing units, this process helps ensure that the water meets the required standards of purity and softness.

Applications of Ion Exchange in Water Softening

- Domestic Use: Hard water can cause scale formation in geysers, washing machines, and other appliances, reducing their efficiency and longevity. The ion exchange process softens the water, thereby protecting household systems and providing better quality water for bathing and cleaning.

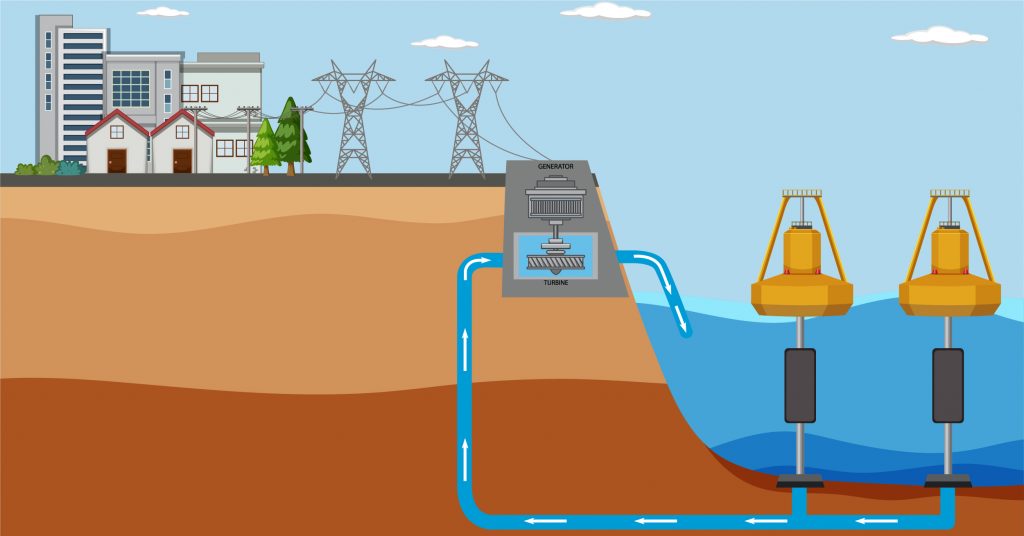

- Industrial Use: Industries such as textiles, pharmaceuticals, power generation, and food & beverage rely heavily on high-quality water. The ion exchange process in water treatment ensures consistent water quality, which is critical for maintaining product standards and operational efficiency.

- Boiler Feed Water Treatment: Boilers are sensitive to water hardness. Even minor scaling can lead to inefficiency and damage. The ion exchange process removes these scale-forming ions, ensuring smooth boiler operation.

- Water Purification Plants: Municipal and private water treatment plants use ion exchange systems as a primary or secondary purification step to treat large volumes of water effectively.

Ion Exchange vs Other Water Treatment Methods

There are several methods available for water treatment, including reverse osmosis (RO), distillation, and chemical precipitation. However, the ion exchange process offers distinct advantages:

- Selective Removal: The process can be tailored to target specific ions depending on the water composition and desired quality.

- Lower Energy Requirements: Unlike RO or distillation, ion exchange doesn’t rely on high pressure or heat, making it more energy-efficient.

- Compact Systems: Ion exchange units are typically compact and require less space, making them ideal for both urban and industrial settings.

Innovations and Advancements

India’s water treatment industry is witnessing continuous innovation. Newer resin technologies with improved selectivity and durability are being developed to enhance the ion exchange process. Hybrid systems that combine ion exchange with RO or UV treatment are also gaining popularity to achieve multi-stage purification. Automation and IoT-based monitoring are making these systems smarter and easier to maintain.

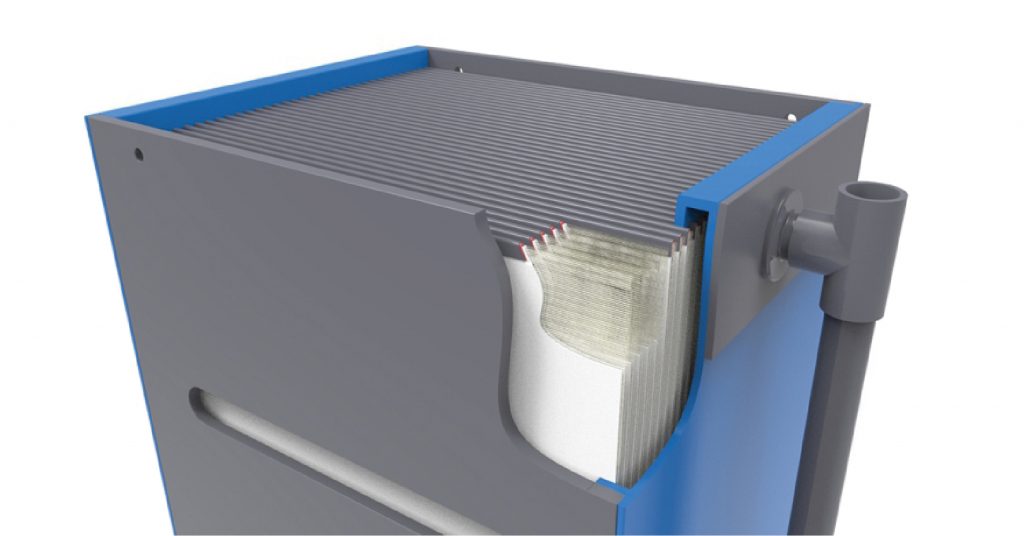

Ion Exchange’s Diverse Range of INDION Resin

The INDION range of ion exchange resins from Ion Exchange stands as the preferred choice across various industries, owing to a legacy of pioneering excellence. Ion Exchange established India’s first resin manufacturing unit in Ankleshwar, Gujarat, which remains one of the largest in the country and is the first to receive both ISO 9001 and 14001 certifications. The manufacturing facility for pharmaceutical-grade resins is USFDA compliant and also WHO-GMP certified, ensuring superior quality and safety. Our extensive range of INDION ion exchange resins is available in Gaussian and Uniform particle size beads, catering to diverse industrial applications in dry and moist forms. Designed with varying surface areas, porosity, and matrix types, these resins are ideal for a broad spectrum of water, non-water, and specialty applications, supporting industries such as pharmaceuticals, food and beverage, nuclear, chemical, bio-diesel, hydrometallurgy, sugar, and beyond.

RANGE OF INDION RESINS: WATER-BASED RESINS

RANGE OF INDION RESINS: NON-WATER-BASED RESINS

- Catalyst Grade Resins

- Adsorbent Grade Resins

- Chemical & Special Process Resins

- Pharma Grade Resins

- Nuclear Grade Resins

- Hydrometallurgy Resins

- Food & Beverage Grade Resins

- Sugar Refining Resins

- Resins for Biodiesel

Conclusion

The ion exchange process plays a crucial role in the water softening and filtration ecosystem in India. Its ability to provide high-quality, soft, and safe water makes it indispensable across various sectors. As the need for efficient water treatment continues to rise, this process stands out as a reliable, scalable, and sustainable solution.