In recent years, industrialization has significantly accelerated in India, driving the growth of various sectors such as manufacturing, textiles, food processing, and chemicals. However, with this growth comes the challenge of handling industrial wastewater. Proper industrial wastewater treatment is essential to protect the environment, conserve water resources, and ensure compliance with regulatory standards.

In this blog, we will explore the key processes involved in industrial wastewater treatment and their significance for Indian industries.

Table of Contents

ToggleWhat is Industrial Waste Water Treatment?

Industrial wastewater treatment refers to the process of treating water that has been used in industrial operations before it is released back into the environment or reused within the facility. The treatment involves several stages, including removing contaminants such as solids, chemicals, and organic materials that pose environmental and health risks. Industries can effectively manage wastewater and minimize its impact by utilizing various industrial water treatment chemicals and systems.

Why is Industrial Waste Water Treatment Important in India?

India’s rapid industrialization and urbanization have led to an increase in wastewater production. Without proper treatment, industrial wastewater can severely damage ecosystems, pollute drinking water sources, and harm public health. The significance of industrial wastewater treatment in India can be summarized as follows:

- Environmental Protection

Untreated industrial wastewater can contaminate rivers, lakes, and groundwater sources, leading to the destruction of aquatic life and ecosystem imbalance. Proper treatment helps mitigate these risks. - Regulatory Compliance

The Indian government enforces strict regulations for wastewater disposal, such as the Environmental Protection Act and the Water (Prevention and Control of Pollution) Act. Industries must adhere to these guidelines to avoid penalties. - Water Conservation

With the increasing scarcity of fresh water, reusing treated wastewater in industrial processes reduces the demand for freshwater sources. - Health and Safety

Industrial wastewater often contains harmful chemicals, heavy metals, and pathogens. Proper treatment ensures the water is safe for discharge or reuse, reducing the risks to human health.

Key Processes in Industrial Waste Water Treatment

1. Preliminary Treatment

The first step in the industrial wastewater treatment process is to remove large solids and debris from the wastewater. This is typically done through:

- Screening: A process that removes large particles, such as plastic and paper, from the water.

- Grit Removal: Grit chambers are used to remove heavy particles like sand, silt, and gravel that could damage equipment or hinder subsequent treatment processes.

2. Primary Treatment

Primary treatment involves removing suspended solids and organic matter through physical methods. This stage typically includes:

- Sedimentation: Suspended solids settle at the bottom of a tank, allowing the treated water to be separated from the sludge.

- Flotation: Oil and grease, which float on the surface, are removed using flotation tanks.

3. Secondary Treatment

This phase targets the removal of dissolved organic matter and biological contaminants. It generally includes:

- Biological Treatment: Microorganisms, such as bacteria, break down organic contaminants in aerobic or anaerobic conditions.

- Activated Sludge Process: Air is bubbled into wastewater to promote the growth of bacteria that consume organic matter.

- Biofilters: These systems use natural filtration media such as sand or activated carbon to treat the water biologically.

4. Tertiary Treatment

Tertiary treatment is the final stage, aimed at further polishing the water to meet the required standards before discharge or reuse. Common methods include:

- Filtration: Additional filtration is used to remove fine particles and microorganisms that remain after secondary treatment.

- Disinfection: The water is treated with chlorine, ultraviolet light (UV), or ozone to kill remaining pathogens and bacteria.

- Chemical Treatment: Various industrial water treatment chemicals, such as coagulants, flocculants, and pH adjusters, are used to remove fine particles, neutralize contaminants, and improve water quality.

5. Sludge Treatment

The sludge generated during wastewater treatment contains concentrated pollutants and requires separate treatment. The process includes:

- Thickening: Sludge is thickened to remove excess water and increase its concentration.

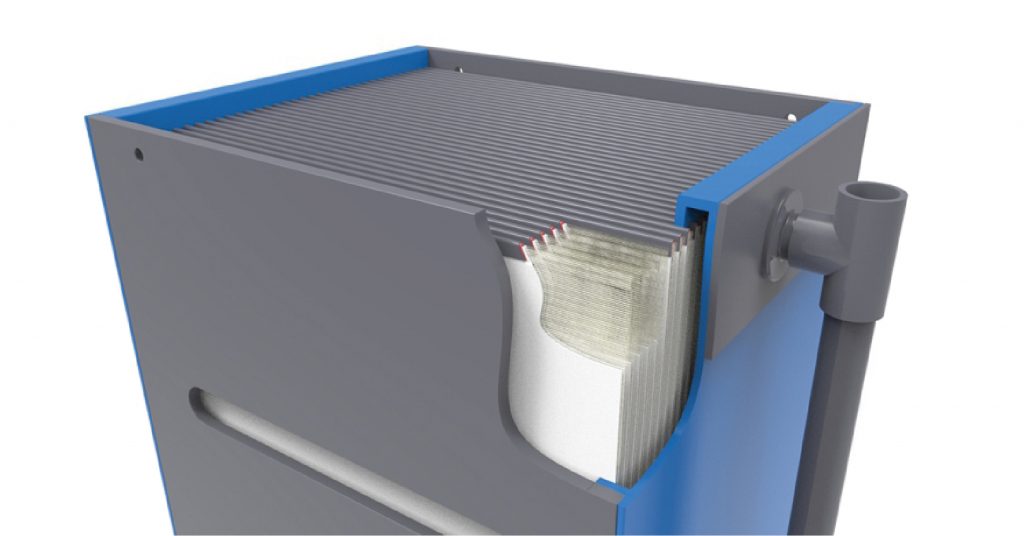

- Dewatering: The thickened sludge is dewatered using equipment such as centrifuges or filter presses.

- Stabilization: Biological or chemical methods are employed to treat the sludge, making it safer for disposal or reuse.

Industrial Water Treatment Chemicals

Industrial water treatment chemicals play a crucial role in ensuring the efficiency of the treatment process. These chemicals help in removing impurities, controlling scale, and preventing corrosion. Some commonly used chemicals include:

- Coagulants: Chemicals that help aggregate fine particles into larger particles that can be removed easily.

- Flocculants: Substances that help coagulated particles bind together to form larger clumps, or “flocs.”

- Corrosion Inhibitors: Chemicals that prevent the corrosion of equipment in water treatment systems.

- Disinfectants: Chemicals like chlorine and ozone that kill harmful pathogens in the treated water.

Benefits of Industrial Waste Water Treatment

- Environmental Protection

Proper treatment helps industries reduce the environmental impact of wastewater and comply with environmental standards, thus protecting ecosystems. - Water Conservation

With water scarcity becoming an issue, the reuse of treated wastewater for industrial processes contributes to water conservation and sustainability. - Cost Savings

Treatment of industrial wastewater reduces the costs associated with water procurement and disposal. It also helps in minimizing fines for non-compliance with environmental regulations. - Improved Public Health

Effective wastewater treatment ensures that harmful contaminants are removed, reducing health risks for communities near industrial facilities. - Enhanced Reputation

Companies that invest in advanced wastewater treatment systems demonstrate environmental responsibility, which can enhance their reputation among consumers and regulatory bodies.

Cutting-Edge Waste Water Treatment Solutions by Ion Exchange

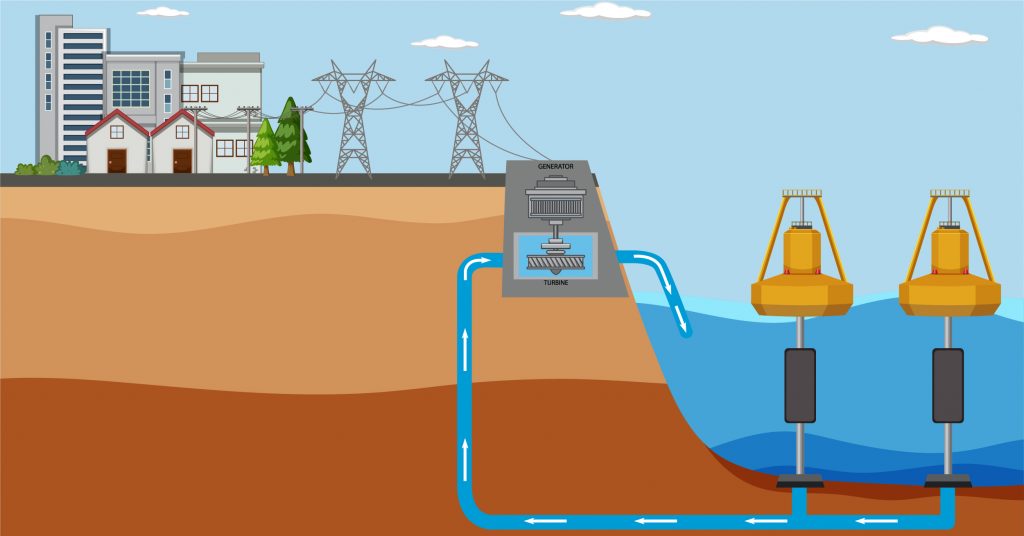

Ion Exchange pioneers water management solutions by focusing on wastewater recycling and source reduction, while their waste management systems emphasize product recovery and waste minimization. They utilize integrated systems that incorporate innovative, energy-efficient, and cost-effective technologies like membranes, advanced oxidation, and evaporation. These systems conserve water by recycling wastewater and recovering valuable products for reuse, achieving zero liquid discharge objectives. This not only provides customers with a strong return on investment but also contributes to environmental protection.

Ion Exchange carefully selects the most appropriate technologies based on thorough studies, surveys, and pilot testing. Their solutions cater to various industries, including power plants, fertilizers, electronics, textiles, chemicals, food & beverage, pulp & paper, pharmaceuticals, and automotive sectors, enabling efficient recovery and reuse of water and products. Our products include:

Conclusion

Effective wastewater management in India is essential for addressing water scarcity, protecting the environment, and supporting economic growth. Key techniques such as primary, secondary, and tertiary treatment, sludge management, and the use of advanced technologies like ultrafiltration play a crucial role in the efficiency of wastewater management plants. With the right expertise, investments, and innovative solutions, India can overcome its water management challenges and secure a sustainable water future.

Connect with Ion Exchange’s wastewater management specialists to learn more about advanced treatment technologies.