India’s chemical and textile industries are among the largest contributors to the country’s manufacturing growth. However, they are also two of the most water-intensive sectors, generating large volumes of wastewater containing dyes, salts, acids, solvents, heavy metals, and complex organic compounds. Managing this wastewater responsibly is no longer optional. Effective effluent treatment is critical for regulatory compliance, environmental protection, and sustainable industrial growth.

With stricter pollution control norms and rising water scarcity, industries are increasingly investing in advanced industrial effluent treatment systems that not only treat wastewater but also enable reuse and resource recovery.

Table of Contents

ToggleWhy Effluent Treatment Is Crucial for These Industries?

Both chemical and textile manufacturing processes involve multiple wet operations that result in highly contaminated wastewater. Without proper treatment, discharge of untreated effluent can lead to severe river pollution, groundwater contamination, and long-term ecological damage.

Key challenges include:

- High color and COD/BOD levels from textile dyeing and finishing operations

- Toxic chemicals and heavy metals from chemical manufacturing processes

- Variable effluent composition, making treatment complex and inconsistent

- Increasing regulatory pressure from CPCB and State Pollution Control Boards

- Rising freshwater costs are making reuse a necessity

A well-designed effluent treatment plant helps industries address these challenges while improving operational efficiency and sustainability.

Understanding Effluent Treatment in Chemical and Textile Plants

Effluent treatment involves removing physical, chemical, and biological contaminants from wastewater before discharge or reuse. In chemical and textile units, the process is typically multi-stage, ensuring thorough purification.

Key Stages of an Effluent Treatment Plant

- Preliminary and Primary Treatment

Screening, oil separation, and equalization to remove large solids and balance flow and pollutant loads. - Chemical Treatment

Coagulation, flocculation, and neutralization to remove color, suspended solids, and certain dissolved pollutants. At this stage, specialized effluent treatment chemicals play a vital role in destabilizing contaminants for easier removal. - Biological Treatment

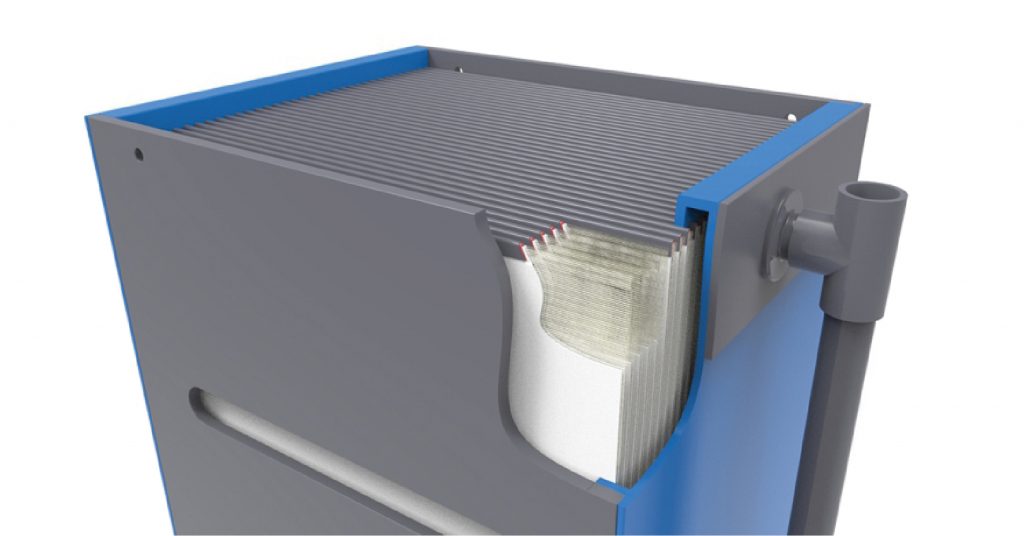

Aerobic or anaerobic processes break down organic matter, significantly reducing BOD and COD. - Tertiary and Advanced Treatment

Filtration, membrane processes, and advanced oxidation to remove residual color, salts, and micro-pollutants. - Sludge Handling and Disposal

Dewatering and safe disposal or reuse of sludge generated during treatment.

This integrated approach ensures treated water meets discharge norms or can be reused within the plant.

Role of Effluent Treatment Chemicals

In chemical and textile effluent treatment, effluent treatment chemicals are essential for process efficiency and compliance. They help in:

- Removing stubborn dyes and color bodies

- Precipitating heavy metals and toxic compounds

- Controlling pH and reducing scaling or corrosion

- Enhancing sludge settling and dewatering

Ion Exchange offers a comprehensive range of treatment chemicals that are carefully formulated for high performance and environmental safety, enabling consistent results across varying effluent compositions.

Industrial Effluent Treatment and Water Reuse

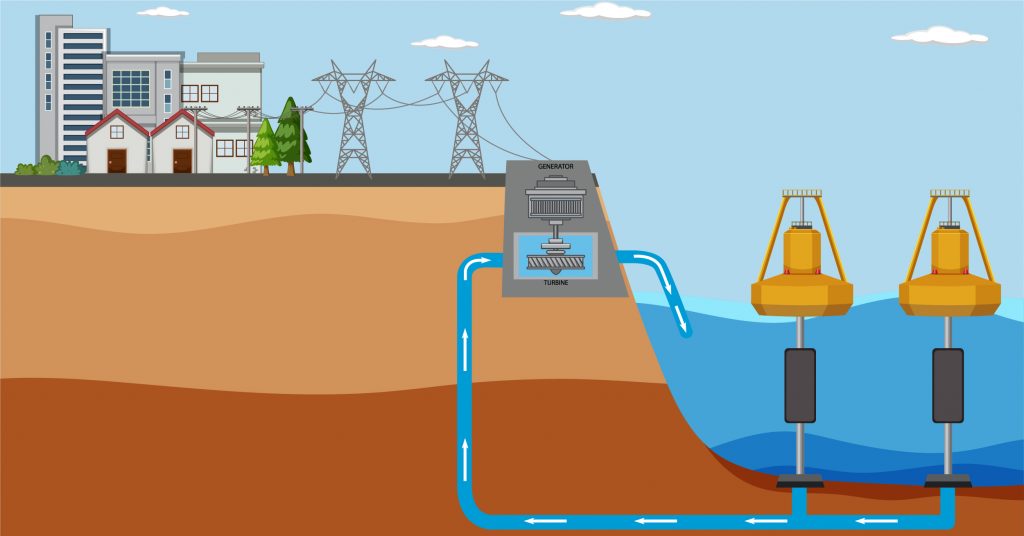

With water scarcity becoming a major concern in India, industries are moving beyond compliance toward recovery and reuse. Modern industrial effluent treatment systems are designed not just to treat wastewater, but to convert it into a reusable resource.

Technologies such as membrane filtration, reverse osmosis, and zero liquid discharge (ZLD) enable:

- Recycling of treated water for process and utility applications

- Recovery of valuable by-products such as salts or chemicals

- Reduction in freshwater intake and discharge volumes

This approach supports environmental sustainability while significantly lowering operating costs.

Ion Exchange’s Leadership in Effluent Treatment Solutions

Ion Exchange has decades of experience in delivering customized effluent treatment plant solutions for the chemical and textile industries across India. Our integrated approach combines engineering expertise, advanced technologies, and high-performance chemicals.

EMPOWERING TATA POWER SOLAR

Tata Power Solar is India’s largest integrated solar company, operating in three segments – manufacturing, EPC services for solar power projects, and manufacturing solar products. For their production facility in Bengaluru, they outsource disposal and treatment of concentrated chemicals and acid rinse with high fluoride content in wastewater. With the goal of implementing an in-house zero liquid discharge facility, they entrusted Ion Exchange with the responsibility of treating and reusing effluent and wastewater. Ion Exchange has designed a 182 m3/day effluent treatment, sewage treatment, and recycling plant consisting of HRSCC-MMF-UF-RO and sludge treatment. For sewage treatment, a state-of-the-art 100 m3/day sewage treatment & recycle plant was designed to help Tata Power Solar comply with Karnataka Pollution Control Board Environmental norms.

GOOD CHEMISTRY

Chiripal Poly Films is India’s leading manufacturer of flexible packaging solutions, producing Biaxially-Oriented Polypropylene (BOPP) films, Biaxially-Oriented Poly Ethylene Terephthalate (BOPET) films, and PET resin chips. It is a part of the Chiripal Group, a multi-faceted business conglomerate. The manufacturing process involves Mono-Ethylene Glycol (MEG) and Ethyl Acetate (EA) as the main constituents. The presence of these organic compounds is responsible for higher toxicity as well as BOD and COD values of the polyfilm effluent. To treat this effluent, Ion Exchange is supplying a 200 m3/day ETP with primary, secondary & tertiary treatment systems. The primary treatment comprises a bar screen – oil skimmer, equalisation cum neutralisation tank, and guard pond. Secondary treatment includes an anaerobic process followed by clarification and an extended aeration system, whereas tertiary treatment involves a chlorine contact tank and a sludge treatment system.

Benefits of Advanced Effluent Treatment

- Regulatory Compliance – Meets CPCB and SPCB discharge standards

- Environmental Protection – Prevents pollution of rivers, soil, and groundwater

- Operational Efficiency – Reduces downtime and process disruptions

- Water Conservation – Enables reuse and supports circular water management

- Cost Savings – Lowers freshwater intake and long-term operating expenses

Conclusion

Effluent treatment is a critical component of responsible manufacturing in India’s chemical and textile sectors. By adopting advanced industrial effluent treatment systems, using high-performance effluent treatment chemicals, and investing in modern effluent treatment plants, industries can protect the environment while improving operational efficiency.

Ion Exchange continues to lead this transformation with proven technologies, innovative solutions, and end-to-end expertise in effluent treatment.

Connect with Ion Exchange experts today to learn how our customized effluent treatment solutions can help your chemical or textile facility achieve compliance, sustainability, and long-term operational excellence.