Cooling towers are essential components of various industries, helping maintain optimal operational efficiency by removing excess heat from processes and equipment. In India, with its growing industrial sector and varied climatic conditions, cooling towers play a crucial role in ensuring uninterrupted productivity. This blog delves into what a cooling tower is, and how a cooling tower works, and provides valuable maintenance and water treatment tips to enhance their efficiency.

Table of Contents

ToggleWhat Is a Cooling Tower?

A cooling tower is a heat exchange system that removes heat from water by evaporative cooling. It is commonly used in industries such as power generation, manufacturing, chemical processing, and HVAC systems. The primary purpose of a cooling tower is to dissipate heat from industrial processes or buildings into the atmosphere, ensuring that machinery and systems operate within safe temperature limits.

How does the Cooling Tower work?

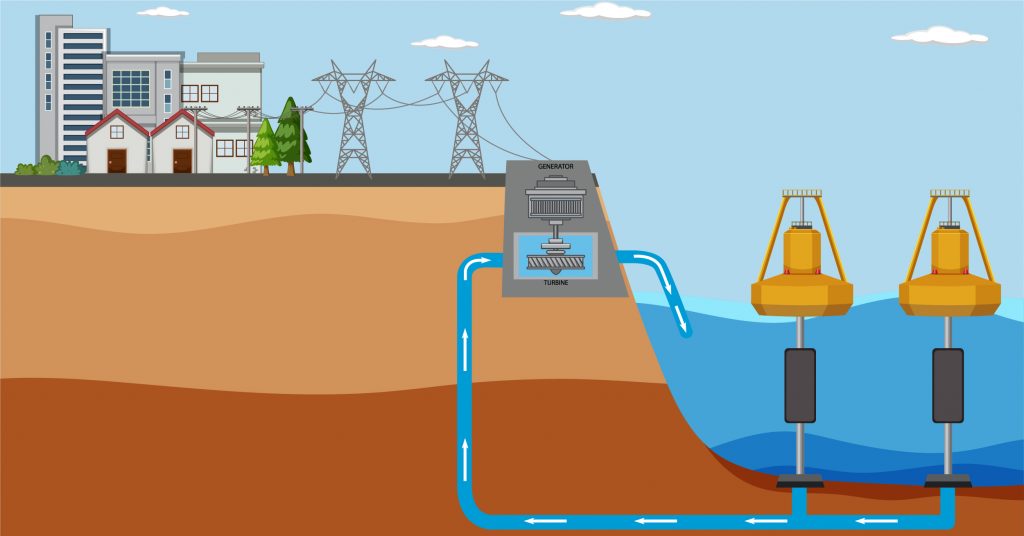

Understanding how a cooling tower works is key to optimizing its performance. The process typically involves:

1. Hot Water Entry

Hot water from industrial equipment or processes enters the cooling tower through an inlet.

2. Water Distribution

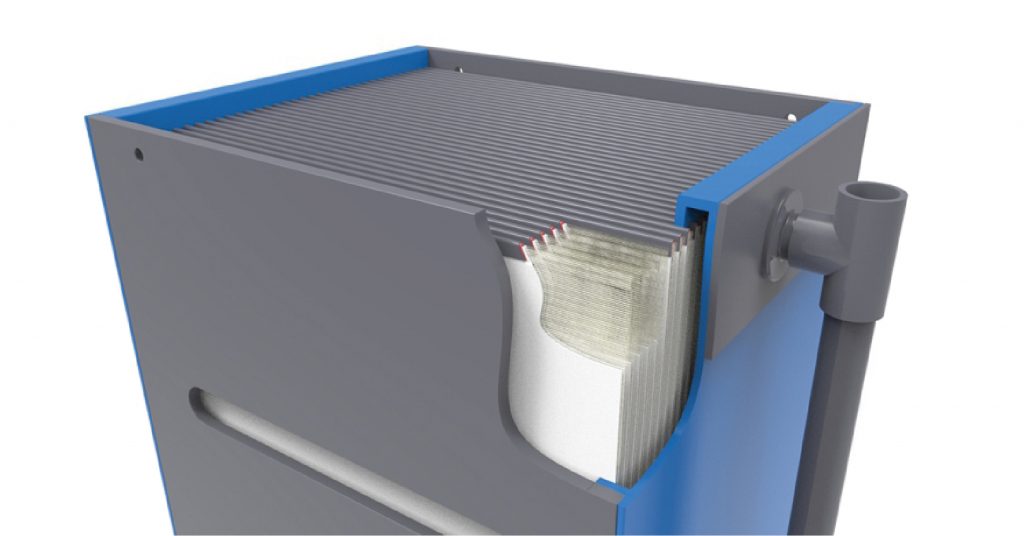

The water is distributed evenly over a fill material, which increases its surface area to maximize heat dissipation.

3. Air Flow

Fans of natural draft systems draw air through the tower, which comes into contact with the water.

4. Heat Exchange

As air passes over the water, heat is transferred from the water to the air. Some of the water evaporates, taking heat energy with it and cooling the remaining water.

5. Cooled Water Collection

The cooled water collects in a basin and is pumped back to the industrial system for reuse.

This process ensures effective heat removal, making cooling towers indispensable for maintaining operational efficiency in high-temperature environments.

Key Maintenance Tips for Cooling Towers:

1. Regular Cleaning

- Remove dirt, debris, and algae from the fill, basin, and nozzles.

- Prevent biofilm accumulation, which can hinder heat transfer.

2. Inspect Components

- Check fans, belts, and motors for wear and tear.

- Ensure drift eliminators and louvers are in good condition to minimize water loss.

3. Monitor Water Levels

- Maintain appropriate water levels in the basin to prevent pump damage.

4. Check for Leaks

- Inspect for leaks in the system and repair them promptly to conserve water and prevent structural damage.

5. Ensure Proper Airflow

- Clean air intake screens and ensure unobstructed airflow to maintain cooling efficiency.

6. Schedule Periodic Maintenance

- Conduct comprehensive inspections and servicing at regular intervals to identify and address potential issues early.

Role of Water Treatment in Cooling Tower Efficiency

Water quality plays a vital role in the performance of a cooling tower. Without proper water treatment, issues like scaling, corrosion, and microbial growth can significantly reduce efficiency and increase operational costs.

How Ion Exchange Sets the Standard for Specialized Water Treatment Solutions?

Our utility water treatment chemical solutions offer comprehensive and efficient treatment and management for raw water, boiler and cooling water systems, membranes, evaporator systems, and wastewater treatment systems. These solutions significantly enhance the performance of utility water systems by safeguarding metallurgy and valuable assets while promoting environmental protection through the safe and reduced discharge of water.

-

Green Chemistry

Additionally, our product range features innovations using Green Chemistry under the INDION brand, ensuring that our chemicals are not only effective but also safe to use, biodegradable, and made from renewable feedstocks. Our commitment to sustainability is further reflected in our advanced technologies for process biocides, antiscalants, scale inhibitors, coagulants, flocculants, and defoamers, all of which cater to the growing industry demand for safe and eco-friendly products.

ION EXCHANGE offers a comprehensive range of cooling water treatment chemicals designed to address various issues like fouling, bio-fouling, and Microbiologically Induced Corrosion (MIC) caused by suspended solids and microbiological organisms. Their solutions include scale control additives, corrosion inhibitors, dispersants, silica scale inhibitors, and specialized programs for deposit and corrosion control. Additionally, they provide a variety of biocides, including oxidizing and non-oxidizing options, as well as advanced chlorine dioxide generators and automatic dosing systems, ensuring optimal performance and protection for cooling water systems.

Conclusion

Cooling towers are essential for industrial processes and large commercial operations in India. Understanding what a cooling tower is and how it works is crucial for optimizing performance and managing water efficiently. As industries continue to grow, the need for sustainable cooling solutions becomes increasingly important.