Boiler water treatment is essential for the efficient and safe operation of boilers. This process involves using various chemicals to ensure that the water used in boilers does not cause scaling, corrosion, or other issues that could lead to equipment failure or inefficiencies. Understanding the types of boiler water treatment chemicals and their functions is crucial for maintaining the longevity and performance of boiler systems.

Table of Contents

ToggleImportance of Boiler Water Treatment

Chemicals used in boiler water treatment are vital for several reasons. Primarily, it helps prevent corrosion and scaling, which can significantly impair boiler performance and lead to costly repairs. Corrosion can cause the metal components of the boiler to deteriorate, while scaling can reduce heat transfer efficiency, leading to higher energy consumption. Effective boiler water treatment ensures efficient operation, prolongs the lifespan of boilers, and helps avoid unexpected downtime and maintenance costs.

Types of Boiler Water Treatment Chemicals

Boiler water treatment chemicals are categorized based on their functions. Here’s an overview of the main categories:

Oxygen Scavengers

- Function: Oxygen scavengers remove dissolved oxygen from boiler water, which helps prevent corrosion. Oxygen is highly corrosive to metal surfaces in boilers, and its removal is essential to maintaining the integrity of the system.

- Common Chemicals: Sodium sulfite, Hydrazine, and DEHA (Diethylhydroxylamine).

Scale Inhibitors

- Function: Scale inhibitors prevent the formation of scale from minerals present in the water. Scale can reduce heat transfer efficiency and lead to overheating and the potential failure of boiler components.

- Common Chemicals: Phosphates, Polymers.

Corrosion Inhibitors

- Function: Corrosion inhibitors protect metal surfaces within the boiler from corrosion. They form a protective film on the metal surfaces, reducing the impact of corrosive substances.

- Common Chemicals: Amines, Phosphonates.

Alkalinity Boosters

- Function: Alkalinity boosters maintain appropriate pH levels in the boiler water, preventing corrosion caused by acidic conditions.

- Common Chemicals: Sodium hydroxide, Sodium carbonate.

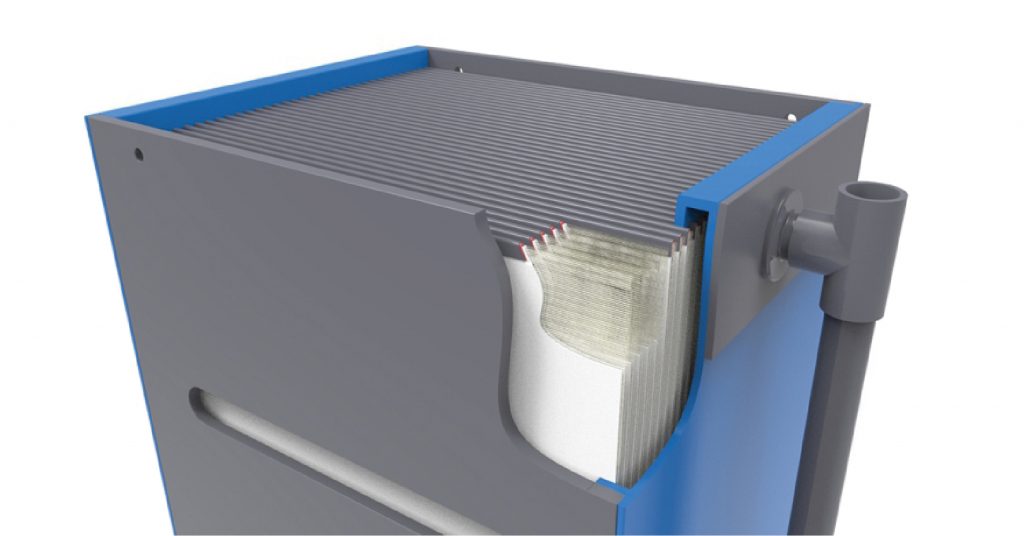

Ion Exchange Boiler Water Treatment Chemicals

- Function: Ion exchange boiler water treatment chemicals soften water by removing hardness ions such as calcium and magnesium, which can cause scaling.

- Common Chemicals: Cation exchange resins, anion exchange resins.

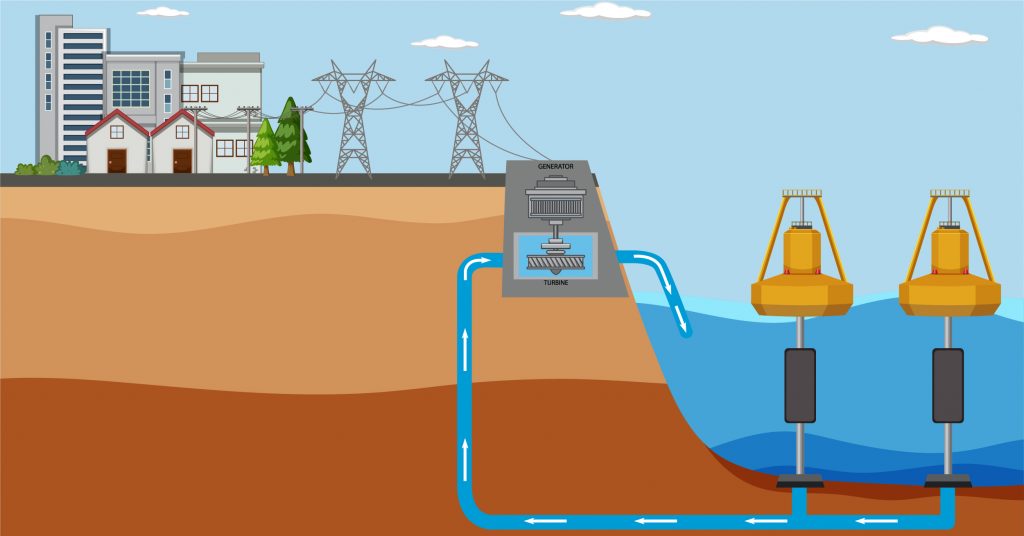

Ion Exchange: Leading the Way in Sustainable Water Solutions

Ion Exchange offers a comprehensive range of specialized, customized chemical treatment programs designed to complement engineered water treatment systems, ensuring optimal plant performance. Our team of highly trained experts conducts thorough surveys of your plant and system requirements, meticulously monitors the treatment programs, and regularly evaluates the results to make necessary adjustments. This diligent approach guarantees that our solutions not only meet but exceed performance expectations, contributing to the efficient and sustainable management of water resources and ultimately refreshing the planet.

Comprehensive INDION® Boiler Water Treatment Solutions

We offer a wide range of boiler water treatment programs for low-, medium-, and high-pressure boilers to prevent deposits and corrosion in pre-boiler, boiler, and post-boiler systems. Our unique DEHA-based oxygen scavengers provide superior protection against corrosion, even in condensate lines. Our treatment solutions include:

- Phosphate treatment program

- Carbonate treatment program

- Chelant program

- Closed system treatment

- Electric boiler treatment

- Sludge conditioners

- Anti-foamers

- Oxygen scavengers

Our complete condensate line treatment programs are designed to solve specific corrosion problems:

- Filming amines

- Neutralizing amines

- Combination of filming and neutralizing amines

These specialized programs ensure the efficiency and longevity of your boiler systems by addressing the distinct challenges faced in different stages of boiler operation.

Boiler Feed Water Treatment Chemical Calculations

Accurate dosage of boiler water treatment chemicals calculations are essential for effective treatment. Overdosing or underdosing chemicals can lead to adverse effects such as scaling, corrosion, or inefficiency.

Correct chemical dosages ensure that the chemicals used in boiler water treatment are effective without causing harm to the boiler system. It helps in maintaining the desired water quality and preventing operational issues.

How Composition Affects Performance and Selection of Chemicals

The composition of boiler-feed water treatment chemicals determines their effectiveness in addressing specific issues such as corrosion, scaling, and pH control. Selecting chemicals with the appropriate boiler water treatment chemical composition ensures optimal performance and cost-effectiveness.

Conclusion

Proper boiler water treatment is essential for maintaining efficient and safe boiler operation. Using the right boiler-feed water treatment chemicals, such as oxygen scavengers, scale inhibitors, corrosion inhibitors, alkalinity boosters, and ion exchange boiler water treatment chemicals, helps prevent common issues like corrosion and scaling. Accurate dosage of boiler water treatment chemicals calculations and understanding the boiler water treatment chemicals composition of these chemicals are key to their effective application. By selecting the appropriate chemicals used in boiler water treatment and following best practices, boiler systems can achieve optimal performance and longevity.