India, with its rapidly growing population and industrial sectors, faces mounting challenges in managing wastewater. From municipal sewage to effluents discharged by food, pharmaceutical, and chemical industries, untreated wastewater continues to strain ecosystems and public health. One highly effective and sustainable solution is anaerobic wastewater treatment—a process that not only efficiently treats wastewater but also generates useful by-products, such as biogas.

This blog examines the anaerobic process in wastewater treatment, compares the aerobic and anaerobic treatment of wastewater, and highlights its advantages, particularly concerning India’s energy and environmental needs.

Table of Contents

ToggleWhat Is Anaerobic Wastewater Treatment?

Anaerobic wastewater treatment is a biological treatment process that breaks down organic pollutants in the absence of oxygen. It relies on microorganisms (primarily bacteria) to decompose biodegradable matter, producing methane-rich biogas as a valuable by-product.

The process is typically used for high-strength industrial wastewater and sewage sludge that contain large amounts of organic material. It is particularly well-suited to tropical countries like India, where higher ambient temperatures improve microbial activity.

Anaerobic Process in Wastewater Treatment: How It Works?

The anaerobic process in wastewater treatment involves multiple steps carried out by different microbial groups:

- Hydrolysis

Complex organic compounds like fats, proteins, and carbohydrates are broken down into simpler molecules (amino acids, sugars, fatty acids). - Acidogenesis

The simple molecules are converted into volatile fatty acids, alcohols, hydrogen, and carbon dioxide. - Acetogenesis

The volatile fatty acids are further converted into acetic acid, hydrogen, and carbon dioxide.

- Methanogenesis

Finally, methane-producing bacteria (methanogens) convert acetic acid and hydrogen into methane (biogas) and CO₂.

This multi-step microbial process occurs in sealed, oxygen-free reactors such as Upflow Anaerobic Sludge Blanket (UASB) reactors, anaerobic lagoons, or covered lagoons, depending on the type and scale of treatment.

Difference Between Aerobic and Anaerobic Processes in Wastewater Treatment

Understanding the difference between aerobic and anaerobic processes in wastewater treatment is crucial for selecting the right method:

| Feature | Aerobic Treatment | Anaerobic Treatment |

| Oxygen Requirement | Requires oxygen | No oxygen required |

| Microorganisms Used | Aerobic bacteria | Anaerobic bacteria |

| By-products | CO₂, biomass (sludge) | Methane (biogas), CO₂ |

| Energy Usage | High (requires aeration) | Low (self-sustaining) |

| Sludge Production | High | Low |

| Applicability | Municipal wastewater, low-strength effluents | Industrial/high-strength wastewater, sludge treatment |

| Cost | Higher operational cost | Lower operational cost |

While both have their uses, anaerobic wastewater treatment is often preferred for high organic load, energy savings, and sludge minimization.

Benefits of Anaerobic Wastewater Treatment in India

- Energy Generation (Biogas)

A key advantage is the production of methane-rich biogas, which can be used to generate electricity or as a fuel. In India’s energy-deficient rural areas and factories, this offers a renewable, decentralized power source.

- Low Energy Requirements

Unlike aerobic systems that need constant aeration, anaerobic processes consume minimal energy. This makes them more cost-effective in the long run, especially in power-scarce regions.

- Less Sludge Production

Anaerobic systems generate significantly less biological sludge compared to aerobic systems, reducing the costs and complications of sludge handling and disposal.

- Effective for Industrial Effluents

Many Indian industries—especially in the food and beverage, distillery, dairy, and pharmaceutical sectors—discharge wastewater with high organic content. Anaerobic treatment is ideal for such effluents.

- Scalable and Sustainable

The process is scalable from small rural systems to large industrial setups. Its sustainability and potential for carbon credits make it an attractive choice under India’s clean energy and wastewater reuse goals.

- Reduces Greenhouse Gas Emissions

When biogas is captured and used as energy instead of being flared or released, it reduces the overall carbon footprint and supports climate change mitigation efforts.

Applications in India

Several Indian states have already adopted anaerobic wastewater treatment systems:

- Distilleries in Uttar Pradesh and Maharashtra use UASB reactors to treat spent wash and generate biogas.

- Municipal sewage treatment plants in cities like Kanpur and Hyderabad use anaerobic digesters for sludge stabilization.

- Dairy industries in Punjab and Gujarat have implemented anaerobic lagoons to treat high-COD effluents cost-effectively.

As India aims to improve sanitation, industrial sustainability, and energy efficiency under initiatives like the Swachh Bharat Mission and National Bio-Energy Programme, anaerobic technologies are gaining strong government and private sector interest.

Ion Exchange Solutions for Efficient Anaerobic Wastewater Treatment

External Circulation Sludge Bed (ECSB)

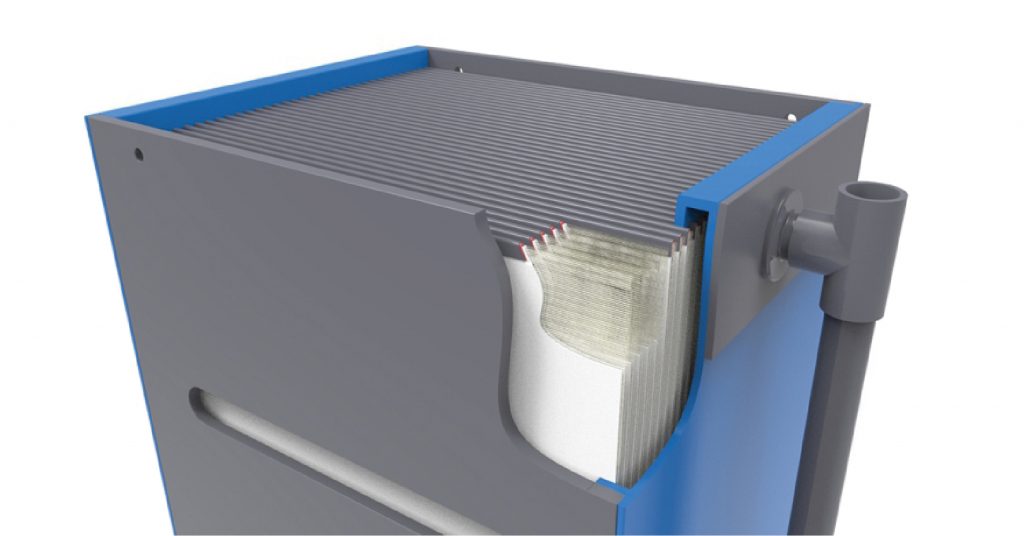

The INDION External Circulation Sludge Bed Reactor (ECSB) is a high-performance anaerobic treatment technology designed for industrial wastewater with high organic loads. Coupled with a wide range of INDION aerobic processes—such as Activated Sludge Process (ASP), Moving Bed Biofilm Reactor (MBBR), Sequencing Batch Reactor (SBR), or Membrane Bioreactor (MBR)—alongside INDION membrane systems like Ultrafiltration (UF), Reverse Osmosis (RO), and Multi-Effect Evaporator (MEE), it delivers comprehensive, cost-effective, and turnkey solutions for wastewater treatment, recycling, and Zero Liquid Discharge (ZLD) requirements. The ECSB features a high-rate tall reactor capable of handling loading rates of 15–35 kg COD/m³/day, ensuring maximum reduction of COD and BOD. Its unique two-phase separator design allows 100% surface area coverage and enhanced biomass retention. The reactor is fully sealed, eliminating odour, and incorporates a patented inlet distribution system that prevents clogging and allows for external cleaning. With the simplest gas handling system and no need for a gas holder, the ECSB sets a new benchmark in industrial wastewater treatment efficiency and reliability.

Up-flow Anaerobic Sludge Blanket (UASB)

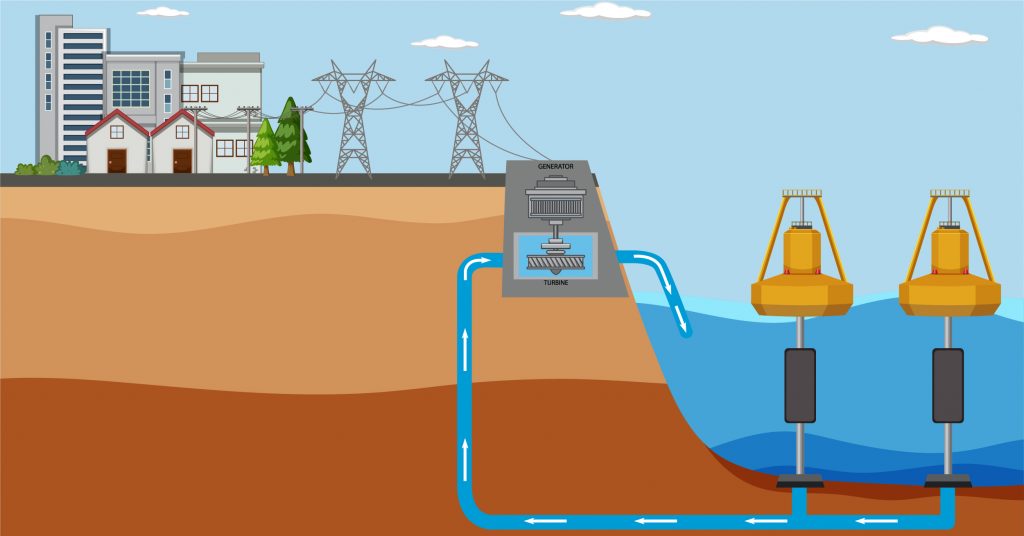

The Up-flow Anaerobic Sludge Blanket Reactor (UASBR) is one of the most widely adopted high-rate anaerobic systems for efficient sewage and industrial wastewater treatment in India. In this process, the influent is introduced from the bottom and flows upward through a dense sludge blanket composed of inorganic particles layered with anaerobic biomass. This blanket not only aids in microbial degradation but also acts as a physical filter, removing suspended solids without the need for prior sedimentation. As the organic matter is broken down, biogas—primarily methane—is generated and collected at the top of the reactor, while the treated water exits from the upper section. UASBR stands out for its low energy requirements, minimal sludge production, and cost-effective operation, making it ideal for treating wastewater of varying strengths. Its applications range from municipal sewage treatment in medium to large towns to handling high-strength effluents from distilleries, pulp mills, slaughterhouses, poultry farms, and large dairy operations.

Conclusion

The anaerobic process in wastewater treatment offers India a sustainable, cost-effective, and energy-positive solution to its growing wastewater management challenges. Understanding the difference between aerobic and anaerobic processes in wastewater treatment helps industries and municipalities choose the right system for their needs. As industrial activities expand and environmental regulations tighten, anaerobic wastewater treatment will play a pivotal role in achieving clean water, clean energy, and circular economy goals across India.